By:

Dean Moyer

Canadian Channel Sales Manager

Published on:

April 24th, 2024

Last updated on:

February 11th, 2026

Topics:

Subscribe now and get the latest blog posts delivered straight to your inbox.

Why Are Isolation Ring Assemblies Used in Water/Wastewater Applications?

By:

Dean Moyer

Canadian Channel Sales Manager

Published on:

April 24th, 2024

Last updated on:

February 11th, 2026

Topics:

Isolation ring assemblies are critical in harsh water and wastewater applications because they protect pressure instruments from clogging, corrosion, temperature effects and mechanical damage that can disrupt system performance. In these environments, pressure measurement instruments are constantly exposed to suspended solids, corrosive chemicals, vibration and temperature fluctuations. Without proper protection, these conditions can lead to inaccurate readings, instrument failure and unplanned downtime.

At Ashcroft, we understand the operational challenges common in water and wastewater systems and how proper instrumentation helps keep those processes running safely and reliably. Read this article to learn how isolation rings function in water and wastewater systems, what application challenges they address and assembly best practices that can help ensure reliable performance over time.

How isolation ring assemblies keep water and wastewater processes running reliably

Isolation ring assemblies protect pressure instruments from direct contact with the corrosive and abrasive process media found in water and wastewater applications. By isolating pressure gauges, switches and transmitters from direct contact with harsh process media, isolation rings ensure accurate, reliable pressure measurement for dependable readings.

These devices are commonly used in pump and system monitoring applications, helping operators identify issues before they lead to equipment damage or process interruptions.

When combined with pressure instruments and protective accessories, isolation ring assemblies help reduce the risk of several common application issues, including:

-

Clogging. Suspended solids and sludge can accumulate inside pressure instruments and cause malfunction or failure

-

Corrosion. Water, sludge and treatment chemicals can degrade metal components over time

-

Overpressure. Pressure spikes and water hammer events can exceed instrument limits and cause damage

-

Vibration. Mechanical vibration can lead to pointer flutter and accelerated internal wear

-

Pulsation. Pump-induced pulsation can fatigue Bourdon tubes or rupture internal components

-

Temperature effects. Elevated media temperatures and ambient temperature changes can reduce measurement accuracy

What accessories are used with isolation rings to protect pressure instruments?

Additional accessories are often used with isolation rings to further protect pressure instruments from damaging process conditions. While isolation rings address clogging and media exposure, other accessories help mitigate specific risks commonly found in water and wastewater systems.

- Pressure-limiting valves prevent overpressure caused by pressure spikes or water hammer

-

Capillary lines or siphons to reduce heat transfer to the instrument.

Selecting the right combination of accessories depends on the process conditions and the type of instrument being protected.

How does temperature affect isolation ring and instrument assembly performance?

Temperature plays a key role in assembly performance because changes in temperature cause the fill fluid inside the sealed system to expand or contract. This creates pressure offsets that affects the accuracy of the measurement. When pressure instruments are mounted to isolation rings or diaphragm seals, these thermal effects can influence both gauge readings and switch setpoints.

The following are several temperature-related effects that must be considered during the assembly design:

-

Pressure gauges. As temperature increases, thermal expansion of the fill fluid creates a positive pressure offset. The lower the instrument range, the greater the percentage error.

-

Pressure switches: Increasing temperature reduces the pressure required to actuate the switch, causing the setpoint to decrease.

-

Digital instruments: Instruments like the Ashcroft® 2274 Digital Pressure Gauge with switch outputs are generally less susceptible to the temperature effects from fill fluid.

Some assemblies use large “goalpost” fittings to mount multiple instruments to a single isolation ring or diaphragm seal. While this approach can simplify mounting, the added internal volume of these fittings increases the amount of fill fluid in the system, which can amplify temperature-related measurement error and contribute to switch setpoint drift.

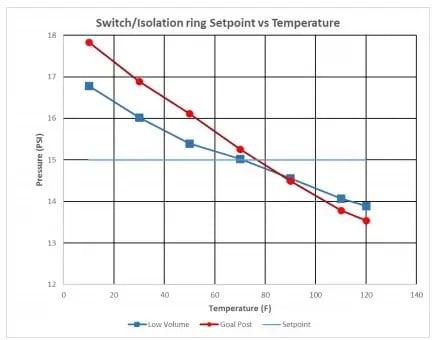

At Ashcroft, custom low-volume fittings with narrow internal diameters are used to minimize the amount of fill fluid required in an assembly. Reducing fill volume helps limit temperature-related error caused by fluid expansion and contraction. As shown in Figure 1, assemblies using low-volume fittings reduced switch setpoint drift by 36 percent due to temperature.

Figure 1. Switch/Isolation Ring Setpoint vs. Temperature

Why does low fill volume matter in isolation ring assemblies?

Low fill volume matters because it reduces temperature-induced measurement error and improves overall assembly stability. Some designs use large internal “goalpost” fittings to mount multiple instruments, but these fittings introduce unnecessary internal volume and increase thermal expansion effects.

Using compact, low-volume fittings with narrow internal diameters minimizes the amount of fill fluid required. Reducing fill volume limits pressure offset and helps maintain more consistent readings across temperature changes. Testing has shown that low-volume assembly designs can significantly reduce switch setpoint drift caused by temperature variation.

How can custom instrument assemblies improve system reliability?

Instrument assemblies can be customized by consolidating components into a single, tested and calibrated unit to improve the reliability of your system. When isolation rings, instruments and accessories are designed and assembled together, installation complexity is reduced and performance consistency is improved.

Working with a single manufacturer to supply, assemble and test the complete assembly simplifies troubleshooting and accountability. If issues arise, having all components sourced and assembled together makes it easier to identify root causes and implement corrective actions.

What are best practices for designing isolation ring instrument assemblies?

When designing isolation ring assemblies, your focus is on reducing stress, minimizing error sources and ensuring compatibility with the application environment. Here are some best practices to try:

-

Minimize the number of fittings used in the assembly to reduce leak paths and installation stress

-

Keep connection sizes consistent to avoid unnecessary adapters

-

Reduce torque and mechanical load on piping and isolation rings using compact fittings

-

Select connection orientations that allow instruments to be read easily and installed without interference

-

Consider alternative gauge connection positions beyond the standard 6 o’clock configuration

-

Verify material compatibility with process media to extend service life

-

Use calibration certificates and hydrostatic testing to confirm accuracy and leak integrity

-

Install isolation valves upstream to protect instruments during startup and pressure testing

Thoughtful assembly design helps reduce long-term maintenance requirements and improves measurement confidence.

Ready to learn more?

Now that you have a better understanding of how isolation ring assemblies are used in water and wastewater applications, you can make more informed decisions to help improve measurement accuracy, protect pressure instruments and support reliable system operation.

Contact us if you have questions about applying these principles to a specific application, and a product expert can help evaluate your operating conditions and recommend appropriate assembly configurations.

For additional insight, download our guide to learn more about instruments and assemblies for water and wastewater applications.

Dean Moyer, Canadian Channel Sales Manager

Dean Moyer is the Ashcroft Territory Sales Manager responsible for the Canadian region. Dean joined Ashcroft in 2004 and is proudly celebrating 20 years of service with the company. He has close to 30 years of experience and expertise in pressure and temperature instrumentation made for all industries including Power Generation, Chemical/Petrochemical, Pharma, Water/Wastewater Treatment and more. Dean attended Seneca Polytechnic in Toronto Ontario.

Topics: