By:

Dave Dlugos

Product Technical Leader

Published on:

March 17th, 2025

Subscribe now and get the latest blog posts delivered straight to your inbox.

What is MEMS Pressure Sensor Technology?

By:

Dave Dlugos

Product Technical Leader

Published on:

March 17th, 2025

This article was originally published on February 14, 2022, and updated on March 17, 2025.

Accurate low-pressure monitoring is crucial for safety in air flow measurement, leak detection systems cleanrooms, isolation rooms and other critical applications in healthcare, semiconductor manufacturing and more. However, measuring very low pressures in small volumes with accuracy and repeatability requires a specialized sensor. It is the sensor’s design, manufacturing process and installation method that will determine whether or not it can deliver the long-term stability, accuracy and resolution necessary to provide meaningful measurements. That's where microelectromechanical systems (MEMS) can help.

Ashcroft, a recognized leader in pressure and temperature instrumentation, and its parent company Nagano Keiki Co. LTD have a proven track record of manufacturing excellence in low-pressure pressure sensors with MEMS technology. Read this article to learn more about MEMS, how it works in low-pressure applications and the pressure sensors available to keep low-pressure environments working with precision and reliability.

What is MEMS?

Generally speaking, MEMS systems are tiny devices that combine mechanical elements, sensors and electrical components. These systems are designed to perform a variety of functions, such as sensing, controlling, and actuating on a micro-scale, allowing them to interact with their environment in precise and efficient ways.

The Ashcroft Si-Glas™ MEMS sensor is designed to create two capacitors that vary as the diaphragm is displaced due to differential pressure. It's composed of sputtered metals and glass molecularly bonded to silicon and does not contain epoxies or other organics to contribute to drift or mechanical degradation over time.

Figure 1: Ashcroft® Silicon Si-Glass™MEMS sensor structure

![]()

Performance expectations of a low-pressure sensor

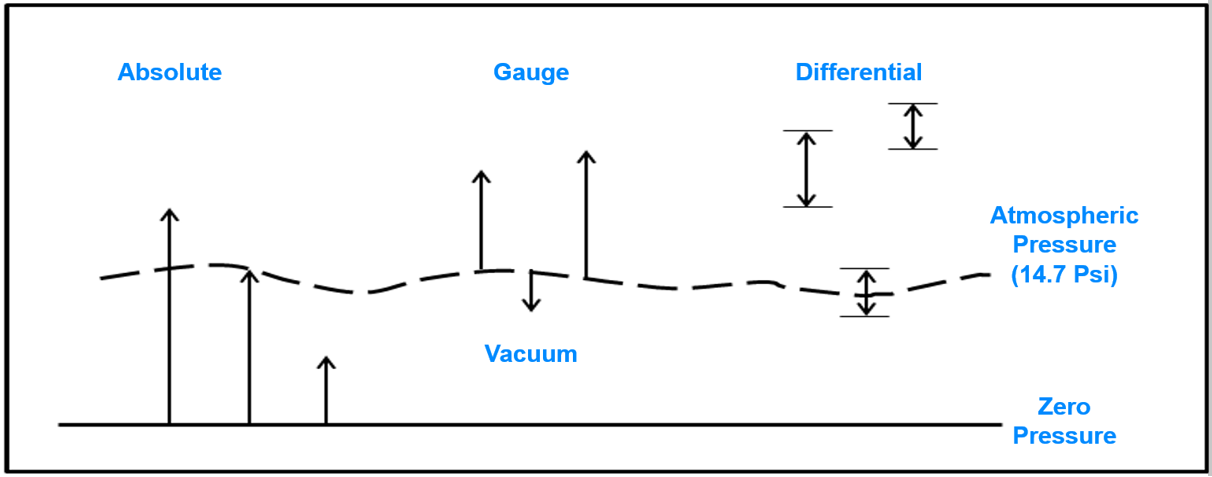

Before we review how a MEMS sensor works, it is important to understand how a low-pressure sensor is intended to perform. So, for this article, we define extremely low pressure as below 10 in H20 (2.49 kPa). Very low-pressure applications always use differential pressure sensors (see Figure 2).

In these cases, we can expect that the sensor will have two pressure inlet ports to measure the difference in pressure between two independent sources. Depending on the installation, the sensor will usually measure the differential pressure between two different environments, often one that is controlled and one that may not be controlled. In many cases, the uncontrolled pressure is simply the barometric pressure inside a building or the outside atmosphere.

Figure 2. Pressure measurement types

When measuring low pressures and small air volumes, the length of the tubing and temperature effects on it can increase or decrease the pressure reaching one side of the sensor, leading to inaccurate sensor readings. These factors must be considered during system design.

How silicon MEMS sensors work in low-pressure applications

Examples of ultra-low-pressure pressure sensors that incorporate a silicon MEMS sensor are the Ashcroft® GXLdp Differential Indicating Pressure Transducer, Ashcroft® DXLdp Differential Pressure Transducer and Ashcroft® CXLdp Differential Pressure Transducer. These state-of-the-art sensors feature Ashcroft® Si-Glas™ technology that combines the high sensitivity of a variable capacitance transducer with the repeatability of a micro-machined, single-crystal silicon diaphragm.

Here's how it works

The Si-Glas™ MEMS sensor is designed to create two capacitors that vary as the diaphragm is displaced due to differential pressure. It's composed of sputtered metals and glass molecularly bonded to silicon and does not contain epoxies or other organics to contribute to drift or mechanical degradation over time.

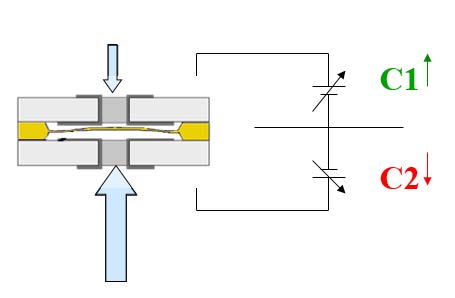

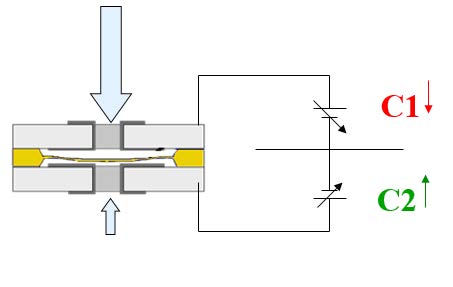

The silicon diaphragm is perfectly elastic, yielding outstanding repeatability, stability and high-proof pressures. When greater pressure is applied to the lower side, the silicon diaphragm deflects upward (see Figure 3). So, the top capacitive signal “C1” increases, while the bottom capacitive signal “C2” decreases. Conversely, when greater pressure is applied to the higher side, the silicon diaphragm deflects downward. The top capacitive signal “C1” decreases, while the bottom capacitive signal “C2” increases (see Figure 4).

Figure 3. Example of what happens when pressure is applied to the lower side of the diaphragm

Figure 4. Example of what happens when pressure is applied to the higher side of the diaphragm

More important features of MEMS pressure sensor technology

Silicon diaphragm sensors using the differential capacitance principle of operation have the advantage of a perfectly elastic diaphragm and are better able to handle overpressure and pressure spikes. Due to their extremely small size and low mass, these are far less sensitive than larger and heavier metal diaphragms.

As they are dead-ended sensors, they can be used in critical/isolation and leak detection systems. However, because they are offered in very low ranges, they will also meet the requirements of most applications.

Industries and applications that use MEMS pressure sensor technology

Three examples of typical very low-pressure applications in which the MEMS sensor would be beneficial include air flow measurement, critical room pressurization measurement, and leak detection. Each of these applications presents its own unique challenges.

Other applications include:

- HVAC/R

- Building Energy Management

- Comfort Control Systems

- Bio-pharm

- Bio-tech

- Clean Room / Laboratory Pressurization

- Room Pressurization and Control

- Velocity Pressure

Ready to learn more?

Now that you know about our MEMS sensor technology and what it can do for your low-pressure transmitters, you can chat with one of our experts to decide if it’s the right solution for your application. If you want to learn more about pressure transmitters for your low-pressure applications, here are a few related resources that can help.

- Ashcroft® Si-Glas™ technology [video]

- Choosing a Low-Pressure Transducer for Critical Environments

- What are the Advantages of Ashcroft Pressure Sensors

- Advantages of Silicon MEMS Sensor Technology [whitepaper]

- How Accurate Are Your HVAC System’s Pressure Instruments?

For more information about pressure and temperature Instrumentation for critical environments, download our guide.

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.