By:

Adam Freyler

VP of Global Marketing and Business Development

Published on:

October 22nd, 2025

Subscribe now and get the latest blog posts delivered straight to your inbox.

How Does Media Temperature Affect Pressure Transducer Performance?

By:

Adam Freyler

VP of Global Marketing and Business Development

Published on:

October 22nd, 2025

This article was originally published on November 30, 2021, and updated on October 22, 2025.

When measuring pressure in challenging environments involving extreme temperatures, your instrument must perform accurately and reliably. Temperature exposure can come from many sources, including the process media and the ambient temperature surrounding the sensor. Each affects the transducer differently, but media temperature has the most direct impact because it acts on the sensing diaphragm and internal components. As media temperature rises or falls, it can distort readings, shorten sensor life or even damage components.

With more than 175 years of pressure and temperature measurement expertise, Ashcroft is recognized as an industry authority in helping customers maintain reliable measurement in even the harshest environments.

In this article, you’ll learn how process media temperature can impact pressure transducer performance, what causes output changes and how to minimize errors through proper design and installation. Understanding this information will help ensure you protect your instruments from performance drift or premature failure.

What is media temperature?

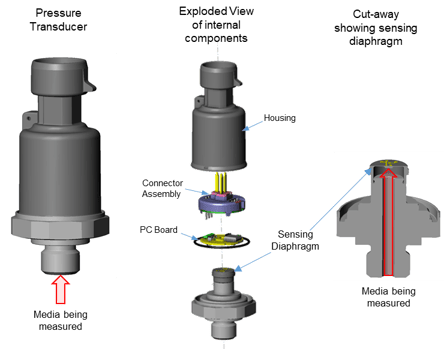

Media temperature refers to the temperature of the process fluid or gas that comes into contact with the sensing element of the pressure transducer. It is different from the ambient temperature, which affects the external housing and electronics. Both can influence performance, but media temperature typically has the greatest impact because it directly affects the sensing diaphragm and internal components.

As temperature changes, the materials inside the transducer—metals, adhesives, and fill fluids—expand or contract at different rates. This expansion and contraction can create stress on the sensing element, causing output changes even when pressure remains constant. If the temperature exceeds the transducer’s rated limit, it can permanently alter the properties of these materials and affect long-term performance.

Figure 1: Pressure Transducer Diagram

How does temperature compensation work?

Temperature compensation works by using internal electronics to sense the device’s temperature and automatically adjust the measurement signal, reducing temperature-related errors. While this enhances accuracy, it is most effective when the entire pressure transducer remains at a uniform temperature. If parts of the transducer heat up or cool down at different rates—for example, during sudden changes in media temperature—uneven temperatures can cause temporary inaccuracies until the whole device reaches thermal equilibrium.

In applications where temperature changes slowly over several hours or days, the transducer is more likely to reach a stable temperature throughout, allowing compensation features to function optimally. However, in situations where media temperature shifts rapidly but the surrounding environment remains steady, targeted mitigation strategies are needed to address the resulting temperature effects on accuracy and stability.

How does temperature affect the mean time between failure?

Fluctuating or extreme temperatures can significantly impact instrument reliability. Temperature cycling introduces mechanical and electronic stress, while prolonged exposure to high operating temperatures is known to reduce the lifespan of electronic components.

To assess expected device longevity, Mean Time Between Failure (MTBF) calculations are commonly used; as a rule of thumb, MTBF typically decreases by half for every 10 °C increase in operating temperature. To enhance reliability and measurement accuracy, it is essential to implement solutions that bring equipment closer to ambient temperature conditions.

To mitigate the effects of temperature, you need to find a solution to make the equipment closer to ambient temperature, which will help with accuracy and reliability.

How to mitigate temperature effects

To protect your measurement instruments from damage, it’s important to ensure that the media temperature does not exceed the product’s specified operating range, which can happen when the transducer is mounted directly to a process line.

Several measurement instrument accessories are designed to help protect your instruments from this risk, including:

Capillary lines

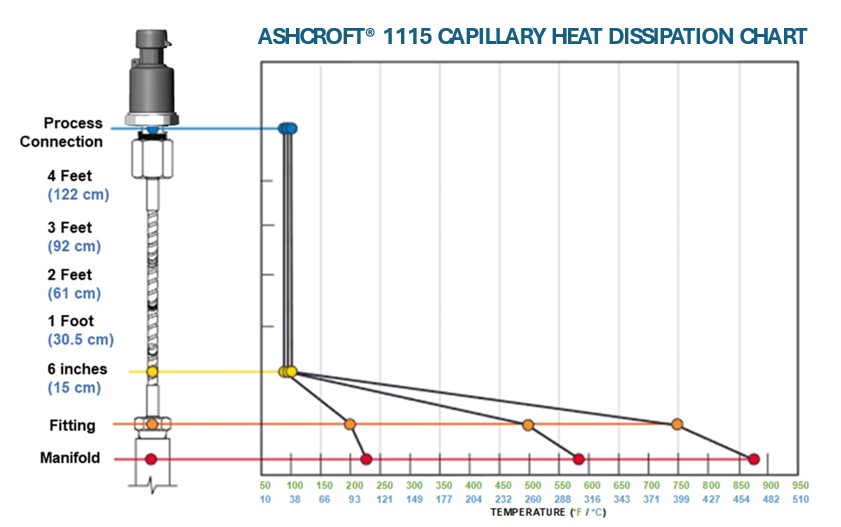

Accessories like the Ashcroft® 1115 Capillary Line create physical distance between the process and the transducer, allowing you to mount the transducer in an area that is less exposed to extreme temperatures. One end of the capillary attaches to the process, while the other connects to the transducer. This arrangement keeps sensitive components away from potentially harmful process temperatures.

By reducing the amount of process media in the line and increasing the surface area exposed to ambient conditions, capillaries help bring the process media temperature closer to a safe operating range. Even a short length—just a few inches or centimeters—can make a significant difference in restoring media temperature to levels that are safe for the instrument (see Figure 2 below).

Figure 2: Capillary Heat Dissipation Chart

Capillaries work well in applications involving gases or liquids that are not expected to have rapid changes in pressure or large amounts of media flow in/out. When flow or rapid changes are expected, there are other solutions to consider.

Diaphragm Seals

Diaphragm seals are used to protect pressure transducers and other instruments when direct process compatibility is needed. They effectively seal and isolate the connection, preventing process media from entering the instrument while still allowing accurate pressure measurement.

It's important to note, however, that diaphragm seals can influence measurement accuracy because additional pressure is required to displace the fill fluid within the seal. This effect on accuracy is more pronounced with seals featuring higher spring rates, fill fluids with greater thermal expansion, and when used on lower-pressure range instruments.

To maintain reliable performance, it is considered best practice to recalibrate the pressure transducer with the diaphragm seal installed at the anticipated operating media temperature.

Steam Siphons

When measuring pressure in steam process lines, special considerations must be taken into account due to the significant energy carried by steam. Traditional accessories, such as extended capillaries, may not adequately reduce temperature because of the continuous movement of steam.

In these scenarios, steam siphons are specifically engineered to protect pressure transducers from elevated steam temperatures. By forming a condensate barrier, steam siphons shield the instrument from direct steam exposure and rapid temperature fluctuations, ensuring accurate measurements and extending the service life of the equipment.

Ready to learn more?

Now that you understand the impact that media temperature can have on your measurement instrumentation, you can research solutions for your application. You can also check out some of our other articles to learn more about transducers and accessories:

- Choosing Transducers for Hydrogen or Hazardous Locations

- How to Select the Right Electronic Connection for Pressure Transducers

- What’s the Right Pressure Instrument Mounting Assembly for Me?

- Isolation Ring Assemblies for the Water/Wastewater Industry

Contact us to get all your instrument questions answered by one of our product experts. In the meantime, download our assembly guide to see what product assembly is best for you.

Adam Freyler, VP of Global Marketing and Business Development

Adam has been our Vice President of Sales and Marketing for the Americas since 2014, leading the company’s sales and marketing teams in the Americas and is responsible for product strategy and driving sales growth in this market. Prior to joining the executive team, Adam was responsible for the sales and marketing of our electronic products. His previous experience includes 10 years in the industrial sensor business including roles in sales management, marketing and engineering at GE Druck and Gems Sensors. Adam earned his B.S. in Physics from the University of Maryland. Adam is an enthusiastic football fan and enjoys fishing, kayaking and spending time outdoors with his family.