By:

Paul Francoletti

Director of Product Sales – Mechanical

Published on:

February 5th, 2024

Subscribe now and get the latest blog posts delivered straight to your inbox.

Understanding Absolute, Vacuum and Compound Pressure

By:

Paul Francoletti

Director of Product Sales – Mechanical

Published on:

February 5th, 2024

This article was originally published on December 13, 2021, and was updated on February 4, 2024.

Different industrial applications require different types of gauges to measure pressure at various points of the process. Mechanical pressure gauges, for example, can be used to measure absolute pressure, vacuum pressure and compound pressure.

If you’re not selecting the appropriate kind of pressure to be measured, your gauge may not provide you with the required “readable” pressure scale.

Ashcroft has been manufacturing pressure and temperature instrumentation since 1852 and as the senior product manager for process gauges, I have been fielding questions on the subject for the past 15 years. In this article, I will take you through the various types of pressure and review the different gauges and transducers available to meet your specific pressure needs.

Pressure Type Definitions

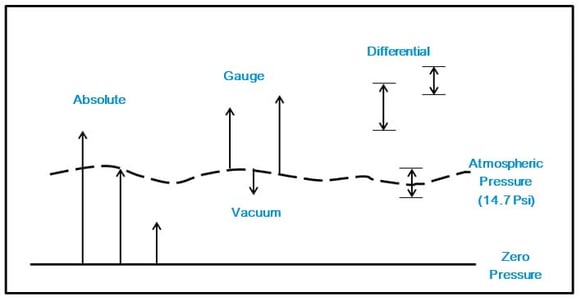

Absolute Pressure - Absolute pressure is measured referenced to absolute vacuum (zero pressure). Absolute vacuum occurs when air is completely absent. Only then is a perfect or total vacuum created. There is no negative absolute pressure.

Gauge Pressure - A positive pressure greater than atmospheric or barometric pressure using ambient pressure as the reference.

Vacuum - A negative pressure less than atmospheric or barometric pressure using ambient pressure as the reference.

Note: there may be specific requirements for gauges that measure both positive pressure and negative pressure, also known as a gauge with a compound range or scale, as well as for gauges that use absolute zero as the pressure point.

What is barometric or atmospheric pressure?

Typically, mechanical pressure gauges are measured and calibrated at atmospheric pressure, also known as barometric pressure or gauge pressure. At sea level, barometric pressure is 30 inches of mercury or 14.7 pounds per square inch (psi).

Interestingly, barometric pressure differs and/or changes depending on elevation. It also varies with weather changes. On a rainy day, barometric pressure falls. Conversely, on a pleasant day, barometric pressure rises.

Recorded barometric pressures in extreme conditions have ranged as high as 25.9 inches of mercury. So, when a pressure gauge manufacturer calibrates the gauge, it is calibrated at the barometric or atmospheric pressure of that day in time, which can change moving forward.

With the extreme weather conditions just described above, when a pressure gauge with a sealed case (not vented to the local atmosphere) is calibrated at sea level or 30 inches of mercury is installed where the barometric pressure is 25.9 inches of mercury, gauge accuracy will be affected by 4.1 inches of mercury or +/- 2 psi.

Typically, changes to barometric pressure do not adversely change a customer’s decision to purchase a mechanical pressure gauge calibrated to atmospheric pressure or gauge pressure.

According to NOAA (National Oceanic and Atmospheric Administration), the average barometric pressure is 29.92 inches of mercury. Typically, pressure instruments use 30 inches of mercury or an equivalent unit of measure as the standard.

What are my options for absolute pressure instruments?

When your application requires absolute pressure, there are a few types of instruments to consider:

Mechanical Pressure Gauges

As a reminder, mechanical gauges are calibrated at atmospheric/barometric pressure of the day. When there is a requirement for an absolute mechanical gauge, often a simple acceptable option is to calibrate the gauge at atmospheric pressure and then at zero pressure, offset the pointer 14.7 psi upscale.

Although not a true absolute gauge with an isolated pressure chamber, this option is often an acceptable and economical choice. See Figures 1 and 2 below for examples of gauges indicating gauge pressure and an absolute gauge with the offset pointer as described above.

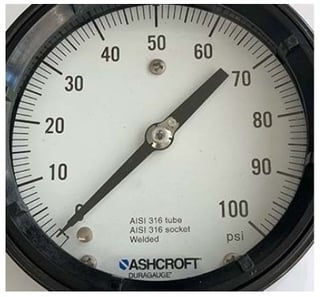

Fig. 1: With standard 0/100 psi gauge pressure

Fig. 2: With 0/100psia absolute pressure

Although some gauges are offered with an isolated chamber making them true absolute gauges, they are costly and not a popular choice.

Digital Pressure Gauges and Transducers

Sensor technology with digital pressure gauges and transducers makes a true absolute pressure range available. Applications include semiconductors, automotive, off-highway vehicles and natural gas equipment.

Vacuum Pressure Gauge

A gauge measuring negative pressure, that is, pressure lower than atmospheric or barometric pressure is called a vacuum pressure gauge. This gauge is calibrated at atmospheric pressure and reads only negative pressure or vacuum. This simply means that the pressure being measured is below atmospheric pressure.

Vacuum pressure gauge dials typically read counterclockwise. The gauge pointer rotates counterclockwise as an increasing vacuum is applied to the gauge. So, on a gauge with a standard 270-degree dial arc, 0 pressure will be in the 270-degree zone.

Fig. 3: Vacuum pressure gauge

Compound Pressure Gauge

Compound pressure measures both positive and negative (vacuum) pressures. A gauge reading gauge pressure only, that is positive pressure, usually will not be damaged if full vacuum is applied to the gauge. However, if it is a requirement to have the gauge dial display both positive and negative pressure, consider a compound pressure gauge.

The pointer will move clockwise when measuring positive pressure and counterclockwise when measuring negative pressure.

Fig. 4: Compound pressure gauge

When would you measure these pressures?

In what situations would someone need to measure for absolute, vacuum or compound pressures? Many applications require these measurements.

Absolute pressure instruments with an isolated instrument sensor are typically used when you need a measurement that’s not impacted by atmospheric pressure. They can be found in weather stations to measure barometric pressure, and in applications that are using air pressure to calculate elevation.

Absolute pressure gauges with a non-isolated sensor, typically a bourdon tube, are used in markets that include refineries, petrochemical plants and chemical plants.

Vacuum gauges require a vacuum pump to remove the pressure. Applications requiring this system include heat pumps, refrigeration, leak detection equipment and air conditioning systems.

Compound pressure gauges can be used to measure for leaks in pressurized lines, or in low-pressure applications like HVAC systems, test chambers in laboratories or any application where both positive and negative pressures need to be read.

Ready to learn more?

Now that you have learned the different types of pressure to measure, let us help you find the right pressure gauge range for your application. Reach out to one of our experts to discuss your process and your measurement needs.

If you want to learn more about pressure gauges and what services we offer for them, here are some more articles we’ve written:

- How To Identify Your Pressure Gauge and Get the Proper Replacement

- How Do I Select the Right Pressure Gauge Range?

- How Often Should I Check the Calibration of My Pressure Gauge?

- How Can I Order Custom Dials for Pressure Gauges?

- How Much Do Mechanical Pressure Gauges Cost?

Feel free to contact us today to talk to one of our industry experts and get all your pressure gauge questions answered.

Paul Francoletti, Director of Product Sales – Mechanical

Paul Francoletti has been with Ashcroft since 2008 and brings extensive experience across EPC and Product Management roles. Throughout his career, he has worked closely with sales teams, channel partners, affiliates, and manufacturing operations to support customer needs and business growth. Paul has also authored numerous educational blog articles, helping readers better understand process and industrial pressure measurement solutions and their real-world applications.