By:

Jessi Jackowski

Product Leader – Diaphragm Seals & Accessories

Published on:

March 19th, 2025

Topics:

Subscribe now and get the latest blog posts delivered straight to your inbox.

How Do I Select the Right Pressure Gauge Range?

By:

Jessi Jackowski

Product Leader – Diaphragm Seals & Accessories

Published on:

March 19th, 2025

Topics:

Pressure gauges can be found in virtually every industry. Depending on your application, these instruments play an important role in measuring the air, gas or liquid pressure in your system to keep it running safely and smoothly. However, for optimum efficiency, you will need to make sure the pressure range you choose for your gauge aligns with your application requirements and a few other factors.

Ashcroft has been in the pressure gauge business for more than a century and a half, so following the guidelines in this article can save you time and give you confidence in your purchasing decision. Read on to learn about the factors to consider when choosing the pressure range for your gauge. Then, when you are done, we will share additional information about pressure gauge selection that you can use as a reference.

Follow ASME's best practices for operating pressure.

The first step in selecting a pressure gauge range is to understand the operating pressures of your process. Ashcroft follows ASME B40.100 standards, which recommend the following:

- Operating pressure should be 25% to 75% of scale, and the gauge range should be twice the operating pressure.

- Ideally, the mid-scale on your dial should be around 12 o’clock, or the mid-scale of the full-scale gauge span.

- If pulsation is present, the maximum operating gauge pressure should not exceed 50% of the full-scale range.

Know the maximum design pressure for your application.

After operating pressure, the next thing you need to confirm is the design pressure. The design pressure is the maximum pressure that your gauge will experience during your application at a given moment in time (not sustained). There can be a surge of pressure when the machine turns on, or surges or pressure spikes can happen at other times during the application.

Pressure gauges can handle 130% to 150% of the range, depending on the range, but if the pressure goes beyond that you will need to get a gauge with a higher range or protect the gauge from inaccuracy issues or possibly overpressure that can cause gauge failure. Both factors are safety issues that should not be ignored. Read, Why Did My Pressure Equipment Fail? 6 Instrument Killers to learn more.

A pressure limiting valve (PLV) can help protect the gauge from overpressure by shutting off the pressure going into the gauge. Consider this accessory when process pressure can at times exceed 130% to 150% of the range.

The PLV is usually set at the full-scale range of the gauge. When the pressure reaches the setpoint of the PLV, pressure into the gauge is shut off, protecting the gauge from overpressure. It will also contain the process media so nothing dangerous leaks out into the environment.

Other gauge factors to consider when choosing a pressure range.

After determining the operating and design pressure of your application, you will need to look at the other factors that can influence the final range you select, including:

Dial Sizes and Features

All pressure gauges have a variety of dial size options and features to consider. Depending on the range you need, dial sizes typically range from 1 ¼ in. to 16 in. Gauge size and readability are very important considerations. The larger the dial, the easier it will be for the operator to read. You can narrow down your options by asking yourself:

- Do I need to read the gauge from a distance?

- How far away is the gauge from the operator?

Dial features on the other hand also consider numeral type, major graduations and minor graduations.

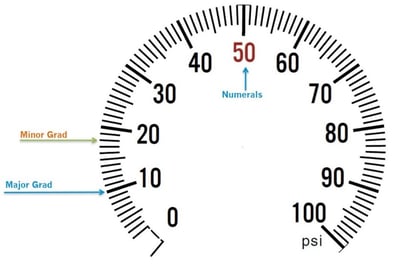

Figure 1: Major and Minor Graduations

Minor graduations can be difficult to read if they’re too close together, so consider the readability of these smaller graduations when selecting the best dial size.

Other considerations:

- Pointer width. This cannot be greater than the width of the dial graduations and may be a limiting factor when determining how many graduations are available with corresponding dial sizes.

- Space restrictions. If there is not a lot of space where the gauge will be installed, you may also be limited in your dial size selection.

- Dial arc. Typically, the dial arc of a gauge is 270 degrees in accordance with ASME B40.100 guidelines. However, some dial arcs are less than 270 degrees.

- Low-light conditions. If your gauge needs to be read in dimly lit areas, using a retroreflective dial material like the Ashcroft Duravis™ gauge dial is a good option. The retroreflective material is the same material used on stop signs. Unlike a reflective material that disperses light in different directions, Duravis™ material reflects light back to the light source, making readability easier. See Figure 2 below.

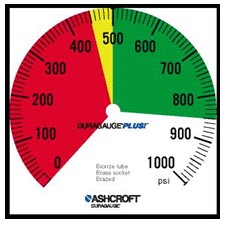

- Customization. Ashcroft offers a variety of printing options for your dials. We can add your logo, use your brand colors, create special dial markings, add color zones and more to accommodate and personalize the gauge for the application. Figure 3 below is an example of a colored zone dial using green to indicate a safe zone, yellow to indicate caution and red for danger.

Figure 2: Ashcroft® Duravis™ Gauge

Figure 3: Colored Zone Dial

Scale Options

When it comes to gauge scales, you will want to confirm the following which can also affect the range:

- Which unit of measure is required? In the U.S., a pound of force per square inch or PSI is common. Other popular units of measure include kPa, kg/cm2 and bar.

- How many units of measure are needed? If your application requires a dial with multiple units of measure, you can select a single, dual, triple or quadruple scale option. Regardless of the one you choose the dominant scale that will be read most will be the inner scale where the numerals and graduations are larger than the outer scale.

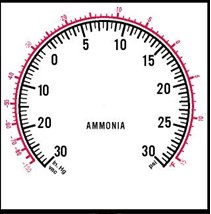

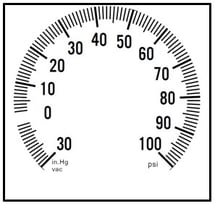

- Whether you need a refrigerant scale. Refrigerant scales like ammonia or refrigerants R11, R12 and 134A can measure both pressure and a corresponding temperature scale. Refrigerant scales that measure both pressure and vacuum are common. Typical units of measure are inches of mercury or millimeters of mercury. When there is a need to measure both pressure and vacuum, a compound scale is available (see Figures 4 and 5 below).

Figure 4: Ammonia Scale

Figure 5: Compound Scale

Accuracy considerations

Generally speaking, the better the accuracy of the gauge, the more graduations are required. So, if your application requires ±0.5% accuracy or better, a dial size less than 100 mm is not recommended. That’s because the number of required graduations can make the gauge difficult to read.

Minor dial graduations generally do not exceed twice the accuracy of the gauge. As an example, a 100 psi range gauge with a required accuracy of ±0.5% will have minor graduations of 1 psi (refer to Figure 1).

In situations where you require a gauge with better accuracy, this usually means more graduations on your dial. In these cases, consider getting a dial that’s a larger size to accommodate the measurement increments.

Ready to expand your knowledge of pressure gauges?

A pressure gauge is a small but significant part of any application. That's why selecting the right pressure range for your gauge is critical for ensuring your instrument performs as it should. If your gauge range doesn't consider all of the factors stated above, your operation can be at risk of failure. For your reference, here are some related resources that may interest you.

- Choosing the Right Pressure Gauge Dial Size

- How To Properly Store Your Pressure Gauge

- How To Identify Your Pressure Gauge and Get the Proper Replacement

- How Often Should I Check the Calibration of My Pressure Gauge?

- Rupture, Proof and Overpressure of Ashcroft Bourdon Tubes

Feel free to contact us today to talk to one of our industry experts and get all your pressure gauge questions answered. In the meantime, check out our pressure gauge selection tool to help you find the best instrument for your needs.

Jessi Jackowski, Product Leader – Diaphragm Seals & Accessories

Jessi Jackowski joined Ashcroft in 2019 as an Inside Sales Specialist before transitioning to the OEM team as a Group Lead. Today, she is the product leader for diaphragm seals and accessories. Prior to Ashcroft, Jessi was the Head Inside Sales Representative for an industrial manufacturer specializing in electrical, automotive, and plumbing tooling. Jessi holds a B.S. in History Education from Southern Connecticut State University. In her free time, she enjoys traveling, spending time with family, and visiting the beach.

Topics: