Subscribe now and get the latest blog posts delivered straight to your inbox.

Choosing the Right Pressure Gauge Size

This article was originally published on July 18, 2022, and updated on April 28, 2025.

There are many factors to consider when selecting your pressure gauge size, including how and where it will be used, gauge readability, distance from the operator and more.

As a leading authority in pressure gauges, Ashcroft is often asked which pressure gauge size is best for a particular application. Unfortunately, there is no simple answer. However, we can help guide you. Read this article for expert insights and additional resources that can help deepen your knowledge about pressure gauges.

Readability is an important factor in pressure gauge size

Gauge size and the ability to read the gauge go hand in hand. A larger dial size significantly enhances readability, allowing operators to quickly and accurately interpret the measurements displayed. This is particularly important in environments where accurate readings are critical.

A larger dial provides a clearer view of the scale and the minor divisions on the scale, reducing the likelihood of errors and improving overall efficiency in monitoring pressure levels.

Figure 1: Operator reading a pressure gauge

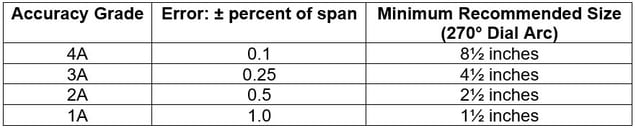

ASME guidelines for optimal gauge size and accuracy

The ASME B40.100 standard provides detailed guidelines and recommendations for the minimum gauge size that should be used in various applications to ensure optimal performance. This standard takes into account factors such as readability, accuracy and the specific requirements of different environments.

Adhering to these guidelines helps ensure that your pressure gauges are both compliant with industry standards and capable of delivering reliable and accurate measurements.

Figure 2: ASME B40.100 minimum recommended gauge size

How distance factors into pressure gauge selection

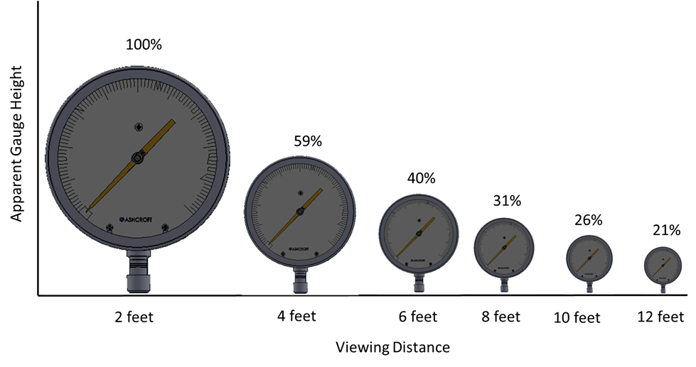

The distance between the gauge and the operator reading is the most important consideration in determining the size of the gauge. To examine how distance affects the readability of a gauge, we took a series of photographs of two gauges (a 6-inch dial size gauge and a 3½-inch dial size gauge) from 2 feet, and then in 2-foot increments up to 12 feet.

We measured the height of the gauge case at each distance and calculated what would be the apparent gauge height at each of the distances (Figure 3). The height is calculated as a percent of the height of the gauge at 2 feet. This should give a better frame of reference. For example, a 6-inch dial size gauge would appear to have a ~1-inch dial size at 12 feet.

Figure 3: Calculated apparent gauge height

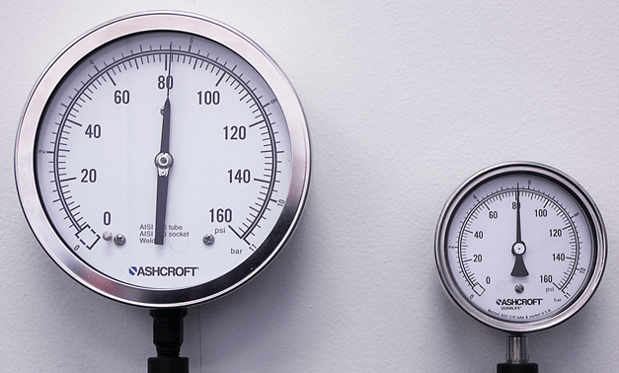

The following series of photos of a 6-in. Ashcroft®1009 Pressure Gauge and a 3½-in. Ashcroft®1009 Pressure Gauge demonstrates the readability of two gauge sizes when viewed side by side. As you can see below, both the 6-in. and 3½-in. gauges can be easily read from 2 feet away.

Figure 4. 6-in. Ashcroft®1009 Pressure Gauge and 3½-in. Ashcroft®1009 Gauges at a distance of 2 feet

At 4 feet, both gauges are still easy to read.

Figure 5. 6-in. Ashcroft®1009 Pressure Gauge and 3½-in. Ashcroft®1009 Gauges at a distance of 4 feet

At 6 feet, both gauges are still easy to read (Note: picture resolution is not as good as eyesight)

Figure 6. 6-in. Ashcroft®1009 Pressure Gauge and 3½-in. Ashcroft®1009 Gauges at a distance of 6 feet

At 8 feet, it’s starting to get hard to read the scale on the 3½-in. gauge. The 6-in. gauge is still readable.

Figure 7. 6-in. Ashcroft®1009 Pressure Gauge and 3½-in. Ashcroft®1009 Gauges at a distance of 8 feet

At 10 feet, it is hard to read the numbers and the scale on the 3½-in. gauge. The 6-in. gauge is still readable.

Figure 8. 6-in. Ashcroft®1009 Pressure Gauge and 3½-in. Ashcroft®1009 Gauges at a distance of 10 feet

At 12 feet, the 3½-in. gauge cannot be read to its stated accuracy. The 6-in. gauge is still readable. If the gauge is used just for a reference, meaning the pointer is in the range of where it should be, then both gauges could be read at 12 feet.

Figure 9. 6-in. Ashcroft®1009 Pressure Gauge and 3½-in. Ashcroft®1009 Gauges at a distance of 12 feet.

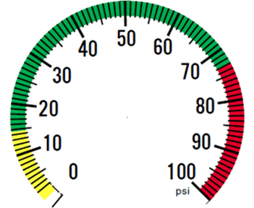

Adding zone markings can help with pressure gauge readability

If your pressure gauge is going to be used as a reference only, adding zone markings (Figure 4) to the dial would make it very easy for the user to read the gauges.

Figure 10: Zone markings on a dial

Comparing common pressure gauge sizes

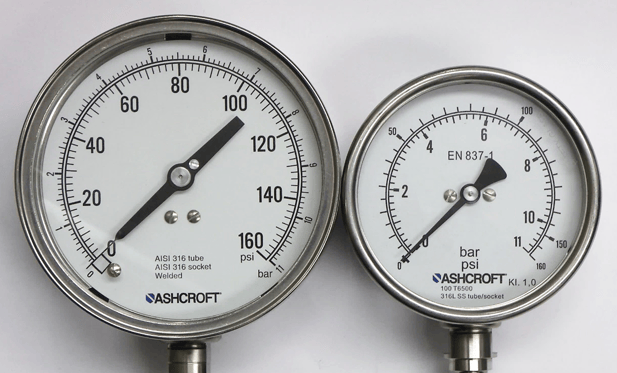

The next set of photos compares common sizes of gauges.

This first photo compares a 4½-in. Ashcroft® 1209 Process Gauge and a 100 mm Ashcroft® T6500 Process Gauge. As you can see, the 4½-in. 1209 is much larger than the 100 mm T6500 with about 65% more surface area.

It is important to note that with a gauge built to the ASME B40.100 standard, the size of the gauge is the dial diameter. On the other hand, for gauges built to EN837-1 specifications, like the T6500, the gauge size is defined as the case diameter, not the dial. The 100 mm T6500 actually has a 3½-in. dial.

Figure 11. 4½-in. Ashcroft®1209 Process Gauge and 100 mm Ashcroft® T6500 Process Gauge

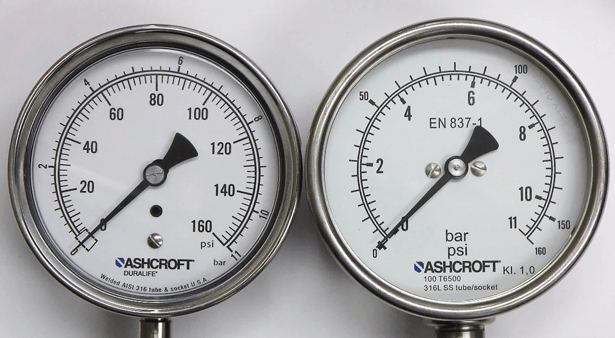

The second photo compares the Ashcroft® 100 mm T6500 to the 3½-in. Ashcroft® 1009 Pressure Gauge. As you can see, they are the same size.

Figure 12. 3½-in. Ashcroft®1009 Process Gauge and 100 mm Ashcroft® T6500 Process Gauge

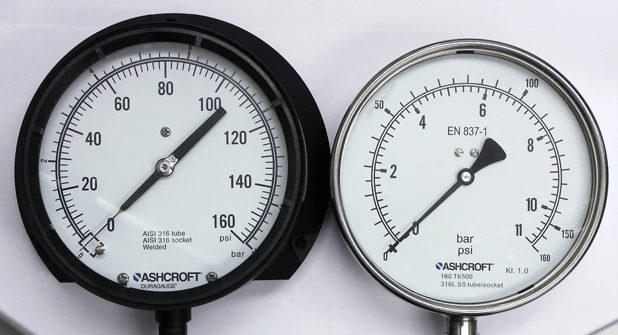

Finally, this third photo compares a 6-in. Ashcroft® 1379 Process Gauge and a 160 mm Ashcroft® T6500 Process Gauge. As you can see, they are also the same size.

Figure 13. 6-in. Ashcroft®1379 Process Gauge and 160 mm Ashcroft® T6500 Process Gauge

Ready to learn more?

You now know that selecting the appropriate gauge size for an application starts with assessing the required measurement accuracy and the distance from which the gauge will be read. For applications that need high precision, a larger gauge size is essential, and measurements should be taken from a closer proximity. However, for reference purposes, a smaller gauge may suffice. Incorporating zone markings on the dial can significantly enhance readability from afar, ensuring effective monitoring across various settings.

For more information on pressure gauges, here are a few other articles we’ve written that may be of interest to you:

- How Much Do Pressure Gauges Cost?

- How Can I Order Custom Dials for Pressure Gauges?

- How To Identify Your Pressure Gauge and Get the Proper Replacement

- How Do I Select the Right Pressure Gauge Range?

- How Often Should I Check the Calibration of My Pressure Gauge?

Feel free to contact us today to talk to one of our industry experts and get all your measuring instrument questions answered. In the meantime, check out our pressure gauge selection tool to help you find the best instrument for your needs.

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.

Topics: