Subscribe now and get the latest blog posts delivered straight to your inbox.

How Much Do Industrial Bimetal Thermometers Cost?

This article was originally published on July 1, 2021, and updated on March 24, 2025.

The thermometer industry is massive. It includes a wide range of temperature-measuring instruments in various shapes and sizes for a multitude of uses. Whether it's a thermometer used to monitor temperature in a chemical plant or one to check your child's fever, the quality and cost can differ significantly.

As a temperature product manager at Ashcroft, a leader in industrial pressure and temperature instrumentation, I have more than 25 years of experience in this field. In that time, I have gained a deep understanding of the pricing and cost factors in the industrial temperature market. While there are too many types of thermometers to cover, read this article to learn what makes bimetal thermometers different from traditional temperature measurement instruments and the factors that influence their pricing.

What makes bimetal thermometers different than other temperature-sensing instruments?

A bimetal thermometer is a specialized instrument designed to measure the temperature of air, gas or liquid in both indoor and outdoor industrial and process environments. These instruments are built for durability, accuracy, and ease of use in demanding settings such as chemical plants, manufacturing facilities, and other industrial applications. They are normally used with protective thermowells to prevent damage from pressure or corrosion.

Unlike traditional thermometers used at home for health purposes, which typically measure body temperature within a narrow range, industrial bimetal thermometers are suitable for monitoring extreme temperature ranges from -100 °F to 1000 °F (-70 °C to 550 °C). However, it is important to note that bimetal thermometers are not intended for continuous use beyond 800 °F (425 °C).

Note: not all bimetal thermometers offer the same level of quality. Before you choose one for your application, make sure the thermometer:

- Is hermetically sealed to prevent fogging from happening in the case

- Is easy to read

- Has a temperature range that meets the requirements of your application

How bimetal thermometers work

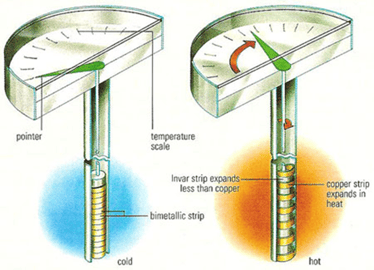

In a separate article about choosing a bimetal thermometer, I explained that these instruments use a mechanical strip made of two bonded metals coiled into a spiral or helix. When heated, each metal expands at a different rate. As the temperature changes, this causes the coil to wind or unwind.

The motion directly connects to the pointer, which glides across a precisely calibrated scale to provide a temperature reading. This simple yet efficient mechanism allows the thermometer to give direct temperature readings without external power sources

Figure 1: How bimetal thermometers work

Factors that influence the cost of industrial bimetal thermometers

Generally speaking, the cost of a bimetal thermometer can range from $20 to $200. The main cost driver of these instruments is the size. The larger the thermometer dial, the easier it will be to read from a distance and the more likely it will be able to accommodate clearer markings to reduce misreadings. This factor comes at a higher cost due to additional materials needed and more time spent on manufacturing. For instance:

- 2-inch bimetal thermometers typically range from: $20 to $100

- 3-inch bimetal thermometers range between $25 and $160

- 5-inch bimetal thermometers can cost from: $45 to $200

In addition to size, the volume of your order will also impact your cost, as well as these other factors:

Bimetal thermometer connection

The connection type of the thermometer, or how it needs to be mounted for optimal visibility, also affects the price. Is the thermometer rear-connected, or does it feature a lower connection? Lower connections tend to be more costly. Additionally, there are "every angle" thermometers, which allow you to view the temperature from any angle, regardless of mounting position, thanks to a dial that rotates 360 degrees.

Figure 2: Bimetal thermometer mounding options

Bimetal thermometer stem length

The length of the thermometer’s stem impacts the cost. The stem can be up to 60” in length. As I mentioned in factor number one, the larger the thermometer, the more expensive it will be. So, the longer the thermometer’s stem, the higher the cost.

Bimetal thermometer material

The material you select for your bimetal thermometer is significant because it directly influences the instrument's accuracy, reliability and ability to perform in different environments. Typically, 304 stainless steel is used because of durability and resistance to corrosion, but for more demanding conditions that involve chemical exposure, 316 stainless steel might be needed. Additionally, opting for either a plastic dial window or shatterproof safety glass can affect the thermometer's resilience to physical impacts and challenging environmental conditions.

Bimetal thermometer with liquid fill

In vibration applications, choosing a silicone liquid-filled thermometer like the Ashcroft® EL Bimetal Thermometer can significantly extend the instrument's lifespan, although it does add to the cost. The liquid fill dampens the effects of vibration, reducing wear and tear on the internal components. Liquid-filled thermometers operate in ranges from -40 °F to 550 °F (-40 to 300 °C).

Tamper-proof vs. externally adjustable

Bimetal thermometers come in externally adjustable or tamper-proof designs. If you need to check and recalibrate the thermometer in the field, an externally adjustable thermometer works. However, a tamper-proof unit has no adjustment, meaning it can avoid any tampering with the temperature indication.

Ready to learn more?

Now that you have a better idea of how industrial bimetal thermometers differ from other temperature measurement instruments, how they work and the factors that influence cost, you are in a better position to select the right one for your needs.

In case you have additional questions, here are a few more articles on relevant topics that can shed more light on the topic of temperature measurement.

- Choosing a Bimetal Thermometer: 5 Factors to Consider

- Gas Actuated Thermometer vs. Bimetal Thermometer

- Fitting a Thermowell to Bimetal Thermometers and RTDs/Thermocouples

- How Much Do Thermowells Cost?

You can also contact a product expert at Ashcroft who can provide more information on a specific product or challenge you are trying to address.

Tino Goncalves, Product Sales Manager

Tino is the Product Sales Manager here at Ashcroft. He has over 20 years of experience in test and measurement instruments and holds a Bachelor of Science in management and electrical engineering.

Topics: