By:

Dave Dlugos

Product Technical Leader

Published on:

June 4th, 2025

Subscribe now and get the latest blog posts delivered straight to your inbox.

How to Fit a Thermowell to Bimetal Thermometers, Thermocouples and RTDs

By:

Dave Dlugos

Product Technical Leader

Published on:

June 4th, 2025

This article was originally published on April 4, 2022, and updated on June 4, 2025.

When installing temperature instruments like bimetal thermometers, RTDs, or thermocouples, a small oversight—such as an improperly fitted thermowell—can lead to costly damage, safety risks or inaccurate readings. Thermowells are essential to protecting your thermometer or temperature sensor and ensuring accurate measurements in high-pressure and high-temperature applications, no matter how extreme the conditions. However, if they are too long or two short for the instrument they need to protect, you will not get an accurate temperature measurement and your instrument can be damaged.

At Ashcroft, a leading authority in pressure and temperature instrumentation since 1852, we are often asked how to properly fit thermowells into various temperature instruments. Because there are so many factors to consider, such as making sure you have the correct measurements, knowing if a u-dimension is needed, remembering to subtract the tip thickness from the overall thermowell length and more, it can be easy to get the wrong size if you aren’t paying attention.

Read this article to learn about thermowells and the different ways to measure your thermometer or RTD/thermocouple for proper installation. When you are done reading, you will understand what each measurement represents and be more proficient in fitting your temperature instrument with a thermowell. You will also see links to additional articles and resources that are available should you need to broaden your understanding of these instruments further.

What Is a Thermowell?

In our Understanding the Basics article, we explained that thermowells are made from solid metal bar stock and are designed to protect temperature instruments such as thermometers, RTDs and thermocouples from damage cause by corrosion, system pressure and high-velocity flow. By preventing these harsh conditions from affecting your instruments, thermowells are also protecting your process equipment and your people.

Thermowells also allow the temperature measurement instruments to be removed without the need to shut down the process, improving both safety and maintenance efficiency.

Basic Thermowell Construction

The first step to properly fitting a thermowell to your temperature instrument is to understand how a thermowell is supposed to fit and what parts to measure. Here are the basic parts of a thermowell, starting from the top of the instrument. (See Figure 1):

- Instrument Connection: Connection of the thermometer into the thermowell (typically ½ NPSM)

- Process Connection: Connection of the thermowell into the process (flange, threaded, etc.)

- Root Diameter: Diameter of thermowell shank just below the process connection

- Internal Bore Diameter: Typically, 0.260 in. or 0.385 in. ID

- Shank: The portion of the thermowell below the process connection

- Tip Diameter: Diameter of the shank at the tip of the thermowell

- Tip wall thickness: between the end of the internal bore and outer tip of the thermowell; typically 0.250 in.

Figure 1: Parts of a Thermowell

Types of Thermowells

To match nearly any temperature measurement device and fit any installation to meet industry standards, thermowells are available in a variety of styles, all of which can accommodated a range of lengths and material options.

Threaded: Screws directly into process connections, is easy to install and is the standard in general industrial applications.

Flanged: Bolts onto a mating flange for a secure, leak-proof seal.

Socket Weld: Welded into the pipe socket to provide a secure seal for high-pressure or high-temperature applications.

Van Stone: Features a loose flange design for easy orientation and replacement without rotating the well or disturbing piping.

Weld-In: Welded into the vessel or pipe wall, offering superior strength and leak resistance for critical process applications.

Sanitary: Designed for easy cleaning and compliance with hygienic standards, so ideal for use in food, beverage and pharmaceutical processes.

Fitting a Thermowell to a Bimetal Thermometer

When installing a bimetal thermometer into a thermowell, three key dimensions must be considered:

- S Dimension (Stem Length): Measures from the thermometer’s fitting to the probe.

- U Dimension (Insertion Length): The distance the well projects into the process.

- T Dimension (Lag Length): The distance from the instrument connection to the process connection.

Tip: Be sure that your thermowell fits in your application first, and then find what bimetal fits in that thermowell. The tip of the probe should touch the bottom, and then you can fill the bottom with a heat-conductive paste.

Other sizing factors include:

Presence of a Lag Extension: this is a spacer between the process connection and the instrument head. It is used to bridge insulation and wall thickness or simply protect the instrument from high process temperatures. If your thermowell includes a lag, you’ll need to ensure the temperature instrument's stem is long enough to reach through the lag and make proper contact with the thermowell tip.

Tank Nozzle or Pipe Wall Thickness:

If the thermowell is being installed into a tank with a long nozzle or a thick pipe wall, the insertion length (U dimension) of the thermowell may need to be increased to ensure it properly reaches into the process media. Neglecting this can result in the sensor measuring ambient or stagnant temperatures rather than the true process temperature.

Standard vs. Custom Thermowells:

While standard thermowells come in fixed lengths and configurations, custom thermowells can be tailored to accommodate special mounting requirements, non-standard thread sizes, unique insertion depths, or demanding process conditions. Customization ensures precise fit and optimal performance, especially when working with legacy systems or non-standard equipment.

Figure 2: Thermowell Measurements with Thermometers

Fitting a Thermowell to an RTD/Thermocouple

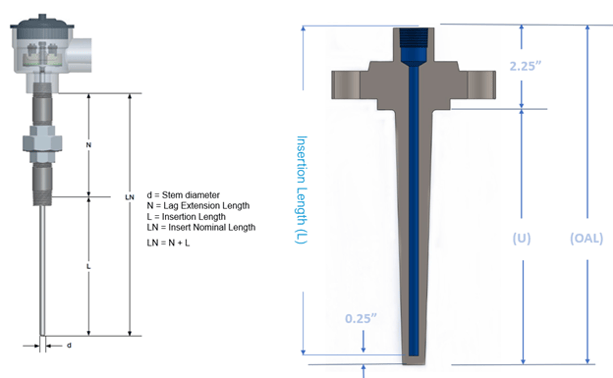

For RTDs and thermocouples, proper fit involves different critical measurements:

- d (Stem Diameter): The diameter of the temperature sensor’s stem that will be inserted into the thermowell. It should match the inner bore of the thermowell closely to minimize air gaps and ensure optimal heat transfer.

- N (Lag Extension Length): The length from the process connection to the point where the sensor head or connection housing begins. It accounts for wall thicknesses, insulation or mounting brackets and ensures the sensor properly reaches into the thermowell without obstruction.

- L (Insertion Length or L Length): This is measured from the bottom threads of the lag extension to the tip of the sensor. It's the part of the sensor that extends into the thermowell and the process. To properly size the thermowell for the RTD or thermocouple probe, you need to subtract the tip wall thickness from the overall length.

L = Overall Length – Tip Wall Thickness

Figure 3: Thermowell Measurements with RTDs/Thermocouples

Tip: Ensure that the spring-loaded probe tip touches the bottom of the thermowell for reliable temperature readings. A loose fit can lead to delayed response or measurement error.

As with bimetal thermometers, you always want to confirm that the thermowell fits the process first—then select or size your RTD or thermocouple accordingly. This approach ensures optimal performance, accuracy, and durability.

Ready to learn more?

Now that you know about the different types of thermowells and the factors to consider when fitting a thermowell to a temperature instrument, you will be able to ensure that your equipment remains safe in your application. For more information on temperature instruments, here are some additional articles that may interest you:

- How to Calculate Thermowell Stem Length for Temperature Instruments

- What is a Thermowell Wake Frequency Calculation?

- How Much Do Thermowells Cost? 5 Factors that Influence Price

- How Much Do Industrial Bimetal Thermometers Cost?

- How Much Do Temperature Sensors Cost?

To speak to someone directly, please reach out to our product experts who can address any additional questions you may have. In the meantime, download our guide to see all Ashcroft® RTD and Thermocouple temperature probe options available to you:

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.