By:

Tino Goncalves

Product Sales Manager

Published on:

November 6th, 2024

Subscribe now and get the latest blog posts delivered straight to your inbox.

Choosing a Bimetal Thermometer: 5 Factors to Consider

By:

Tino Goncalves

Product Sales Manager

Published on:

November 6th, 2024

This article was originally published on March 28, 2022. and updated on November 6, 2024.

In industries such as manufacturing, food processing, chemical production, HVAC and more, maintaining precise temperature measurement is important to ensure product quality and safety. Bimetal thermometers address challenging environments by providing accurate and reliable temperature readings that are necessary to protect your product, your process and your operators.

But how do you determine the best bimetal thermometer for your specific application?

As the product manager for temperature products at Ashcroft, a leader in pressure and temperature instrumentation, I can guide you through the selection process. Read this article to learn more about the functions and applications of bimetal thermometers and the key considerations to help you choose a high-quality option tailored to your requirements.

I will also share some additional resources that can answer other questions you may have about these instruments.

When would I use a bimetal thermometer?

Bimetal thermometers are designed to measure the temperature of air, gas or liquid in both indoor and outdoor settings. They are a good choice when you need a reliable, durable and easily readable indication of temperature that can be seen from a distance to help keep operators safe from hazardous areas. They can also serve as a reference to confirm electronic monitoring.

How a bimetal thermometer works

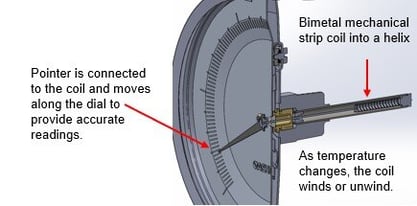

Bimetal thermometers use a mechanical strip made of two bonded metals coiled into a spiral or helix. When heated, each metal expands at a different rate. As the temperature changes, this causes the coil to wind or unwind.

The motion directly connects to the pointer, which glides across a precisely calibrated scale to provide a temperature reading. This simple yet efficient mechanism allows the thermometer to give direct temperature readings without external power sources.

Figure 1. How bimetal thermometers work.

Let’s discuss the factors to consider when selecting a bimetal thermometer.

5 Considerations when Choosing Bimetal Thermometers

When researching for your specific application, keep these factors in mind:

1. What size instrument do you need?

Choosing a bimetal thermometer that is appropriately sized for your specific application is essential for readability. For instance, a larger dial size is easier to read from a distance, which is important in environments where operators cannot always be close to the instrument. A bigger dial can also accommodate larger and clearer markings to reduce the risk of misreading the temperature. Typically, bimetal thermometers are available in various sizes, such as 2-inch, 3-inch, and 5-inch dials, to suit different visibility needs.

2. What type of mounting or connection method is required?

How your thermometer will be mounted to the process for optimal visibility and functionality is also an important consideration. Your options will generally include a rear mount connection (stemming from the back of your instrument), a lower connection (mounting from the bottom), or an "every-angle" option. The Ashcroft® Everyangle™ mounting option features a 360-degree rotating dial that allows you to view the temperature from any position regardless of its mounting location.

Figure 2. Bimetal thermometer mounting options.

3. Which material is best for your application?

The material used in your bimetal thermometer is an important factor because it directly affects the instrument's durability, accuracy, and suitability for specific environments. While 304 stainless steel is commonly used in these instruments for its corrosion resistance and strength, 316 stainless steel may be necessary for harsher conditions requiring resistance to chemical exposure. Also, the choice between a plastic dial window and shatterproof safety glass can impact the thermometer's durability against physical impacts and potentially challenging environmental factors.

4. Do you need a liquid-filled thermometer?

In applications where vibration is a concern, choosing a silicone liquid-filled thermometer like the Ashcroft® EL Bimetal Thermometer can significantly extend the instrument's lifespan. The liquid fill dampens the effects of vibration, reducing wear and tear on the internal components. These thermometers are also capable of operating within a wide temperature range of -40 °F to 550 °F (-40 to 300 °C), making them an ideal choice for processes that are subject to constant movement or shaking.

Bimetal thermometers are available in two primary designs:

Externally adjustable. An externally adjustable thermometer, like the Ashcroft® EI Bimetal Thermometer or the Ashcroft® EL Bimetal Thermometer, is beneficial when quick and minor span adjustments are needed in the field to maintain accuracy.

Tamper-proof. A tamper-proof instrument like the Ashcroft® CI Bimetal Thermometer, is designed without adjustment capabilities. The hermetically sealed case prevents any moisture or corrosion from entering the interior and also prevents coil freeze and unauthorized alterations to the temperature readings.

Ready to learn more?

Now that you understand the factors to consider when selecting a bimetal thermometer, you are more prepared to find the best one for your application. Keep in mind, when using a bimetal thermometer in high-pressure or corrosive applications, be sure to use a thermowell to protect your instrument from damage.

For your reference, I have included links to additional articles that may be of interest to you:

- Gas Actuated vs. Bimetal Thermometers

- What is a Thermowell?

- How Much Do Industrial Bimetal Thermometers Cost?

- How Much Do Thermowells Cost? 5 Factors that Influence Price

At any time, please feel free to Contact our product experts with any questions about temperature measurements or instrumentation.

Tino Goncalves, Product Sales Manager

Tino is the Product Sales Manager here at Ashcroft. He has over 20 years of experience in test and measurement instruments and holds a Bachelor of Science in management and electrical engineering.