Subscribe now and get the latest blog posts delivered straight to your inbox.

Best Pressure Instruments for Ammonia Plant Applications

This article was originally published on January 9, 2023, and updated on September 10, 2025.

If you work in ammonia production, you already know the process isn’t gentle on equipment. Corrosive media, extreme temperatures and unexpected pressure spikes can take a toll on your equipment. Using instruments that aren’t built for these conditions can lead to inaccurate readings, costly repairs, downtime, or safety risks.

That’s where choosing the right pressure gauge makes all the difference. At Ashcroft, we've spent close to two centuries helping engineers protect their systems with instruments designed to withstand demanding environments.

Read this article to learn:

- The key factors to consider when measuring pressure in ammonia plants

- How to protect your instruments from process conditions

- Why the Ashcroft® 1209 Pressure Gauge, 1279 Pressure Gauge and 2198 MicroTube™ Siphon are best suited for the job

Factors to consider when choosing pressure instruments for ammonia service

Ammonia production combines corrosive media, low-temperature liquid service and high-temperature steam. These extremes create unique challenges for pressure instrumentation. When selecting a gauge, it’s important to evaluate:

- Material compatibility. Ensuring wetted parts and fill fluids resist ammonia corrosion.

- Temperature effects. Accounting for liquid ammonia’s low temperature and the steam used in production.

- Vibration and pulsation. Managing pointer flutter and gauge wear from pumps and compressors.

- Overpressure risks. Preventing damage from unexpected pressure spikes in the system.

The following sections break down each of these considerations and how to address them in ammonia plant applications.

What materials are safe to use with ammonia?

Not all materials are compatible with ammonia. For example, brass, zinc and copper should be avoided in wet ammonia service because corrosion can occur. In the Haber-Bosch process, hydrogen is combined with nitrogen to make ammonia, and that nitrogen is not compatible with glycerin. That means glycerin-filled gauges should also be avoided. And, finally, Viton® elastomers don’t hold up well in ammonia service, so they should not be used.

Better choices include:

- 316 stainless steel for wetted components (preferred for corrosion resistance)

- Carbon steel or silicone components in supporting parts

- Solid-front case gauges, which help protect operators if a bourdon tube fails under pressure

For more detail, you can use Ashcroft’s Material Selector/Corrosion Guide, which outlines compatibility across a wide range of process media to help ensure the materials you choose are a safe match for ammonia service.

How to protect pressure instruments from extreme temperatures in ammonia applications?

Liquid ammonia averages around –32 °F, which can exceed the limits of standard gauges. If an instrument isn’t rated for these low temperatures, you will need a capillary line between the process and the gauge to offset conditions.

On the other end of the scale, steam used in ammonia production requires high heat. To prevent instrument damage, accessories such as pigtail siphons or coil siphons should be properly fitted and filled with water to create a barrier between the direct steam and the wetted parts of the instrument.

For systems where high temperatures are present, the Ashcroft® 2098 Mini-MicroTube™ siphon provides superior heat dissipation. It:

- Handles up to 3,000 psi and 600 °F

- Has a compact design for limited-space installations

- Protects gauges, switches, and transducers from elevated temperatures

How to manage the effects of vibration and pulsation on your pressure gauge?

If your system involves pumps, compressors or other sources of mechanical movement, pulsation and vibration (common in ammonia plants) can cause significant performance issues on pressure gauges. A dry gauge exposed directly to vibration is often difficult to read and has a shortened service life.

Options for managing vibration and pulsation

- Liquid filling: A silicone-filled gauge (avoid glycerin in ammonia service) lubricates the movement, dampens pointer motion, and changes the resonant frequency of the gauge. The result is a steadier pointer and extended gauge life.

- Remote mounting: In extreme cases, you can mount the gauge on a column, bulkhead or panel away from the vibration source using a flexible capillary line. This isolates the gauge from vibration and acts as a flow restrictor, reducing pulsation severity.

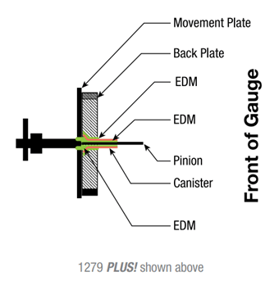

- PLUS!™ Performance: Ashcroft’s award-winning dry case technology offers an alternative to liquid fill. It uses a proprietary Engineered Dampening Media (EDM) injected into a canister that surrounds the gauge movement pinion shaft, movement plate and backplate (see figure 1 below)

Figure 1: Diagram of Ashcroft’s PLUS!™ Performance

What overpressure concerns in ammonia systems?

If a gauge is exposed to pressure spikes beyond its design, the bourdon tube may become distorted. This leads to a calibration shift and increases the operating stress on the tube. High stress raises the risk of metal fatigue, which can result in bourdon tube failure and loss of process containment.

To minimize risk, you can:

- Size the gauge so normal operating pressure is about 50% of the full-scale pressure. ASME B40.100 recommends that the normal operating pressures for a gauge should be confined to 25-75% of the full scale.

- Consider overload stops or pressure-limiting accessories where surges are expected

Which pressure gauges are best for ammonia plant applications?

While most Ashcroft products with 304/316 Stainless steel wetted components can be used in ammonia applications, two gauges stand out for ammonia service because they directly address the key challenges of material compatibility, vibration, temperature extremes and overpressure risks:

Ashcroft® 1209 Process Gauge

- Built with 316L stainless steel wetted parts, making it highly resistant to ammonia corrosion.

- Its solid-front case design provides operator protection if the bourdon tube fails under extreme pressure.

- Optional PLUS!™ Performance dampens pointer flutter caused by vibration or pulsation, reducing fatigue on the gauge and improving readability in noisy plant conditions.

- Designed for high accuracy (±0.5% of span), which supports reliable monitoring in critical ammonia processes.

Ashcroft® 1279 Duragauge® Pressure Gauge

- Offers broad material options, including 316L stainless steel, to withstand ammonia’s corrosive effects.

- Handles a wide range of pressures, from vacuum up to 30,000 psi, making it suitable for ammonia systems that see both low- and high-pressure service.

- The phenolic solid-front case with a pressure relief back adds an extra level of operator safety in the event of failure.

- Like the 1209, it is available with PLUS!™ Performance or liquid fill to address vibration, pulsation, and pointer flutter.

By choosing gauges with solid-front construction, stainless steel wetted parts and vibration-dampening options, you’re directly addressing the same considerations (material compatibility, temperature resilience and dynamic pressure effects) that matter most in ammonia plant applications.

Ready to learn more?

Now that you know the factors to consider when choosing the right pressure instruments for ammonia applications, you are in a better position to select the best solution for your needs. Keeping these factors in mind can help ensure that you avoid problems and keep your process running with reliable and accurate pressure measurements.

If you want to learn more, here are a few more pressure instrument articles that you may find relevant:

- Alternatives to Liquid-Fill Pressure Gauges for Vibration Protection

- Heat Dissipation: Pressure Gauge Accessories for Non-Steam Applications

- How Does Temperature Affect Pressure Gauge Performance?

- Why Did My Pressure Equipment Fail? 6 Instrument Killers

Feel free to contact us to talk to one of our industry experts and get any other questions answered. And, if you’d like to gain insights about keeping your equipment running, download our guide:

Bob Pierce, Territory Sales Manager

Bob Pierce is the Territory Sales Manager (Channels/Distribution), responsible for 6 states in the Southeast Gulf Coast region. He started his career at Ashcroft in 2018 with 25+ years of experience in the fields of Instrumentation and Control Valves. Bob has a Bachelor of Science degree in the School of Business from the University of Alabama – Birmingham.

Topics: