By:

Jessi Jackowski

Product Leader – Diaphragm Seals & Accessories

Published on:

February 26th, 2025

Subscribe now and get the latest blog posts delivered straight to your inbox.

Heat Dissipation Pressure Gauge Accessories for Non-Steam Applications

By:

Jessi Jackowski

Product Leader – Diaphragm Seals & Accessories

Published on:

February 26th, 2025

This article was originally published on October 31, 2022, and updated on February 26, 2025.

If you work in oil and gas, chemical and petrochemical, or any other industry that involves high heat, your challenge is to find instruments that are designed to withstand the extreme temperature conditions of the environment and your process media. For example, pressure gauges have specific temperature ranges. If your application goes beyond the instrument's limits, you may need to add an accessory to maintain the integrity and accuracy of your gauge.

As the accessories product leader at Ashcroft, part of my job involves educating customers and distributors about the options available to keep their systems running safely and efficiently. In this article, you will learn how to protect your pressure gauges from getting damaged in harsh applications. You will also see links to additional articles and resources that will help deepen your knowledge of pressure gauges and the accessories that support them.

Know your pressure gauge temperature range

If you read my article, How Does Temperature Affect Pressure Gauge Performance?, you learned that pressure gauges are designed with specific temperature ranges. Using a gauge for an application that goes beyond its specified range can damage the gauge and jeopardize the safety of your operation and your people.

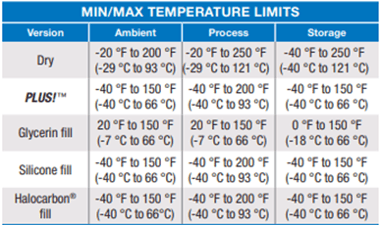

Your gauge's temperature range can vary depending on the type of temperature:

- Ambient. The air temperature that surrounds the instrument.

- Process. The temperature of the media that directly contacts the instrument's wetted parts.

- Storage. The temperature of the storage facility or container that is holding the instrument.

Long-term exposure to extreme temperatures can cause discoloration of the dial and fill fluid, and the hardening of internal gaskets and seals, which can lead to case leaks and impact the accuracy of the gauge.

Another factor that can affect the temperature range of a pressure gauge is the fill that is used (or not used) as a dampener. For instance, a dry gauge (no fill) will have a different temperature range than a gauge filled with Glycerin, Silicone or Halocarbon®.

The table below illustrates the temperature ranges for pressure gauges based on the type of temperature and the fill that is used.

Figure 1: Ashcroft min/max temperature limits

Note: Always refer to the pressure gauge datasheet for the most accurate information.

Accessories to protect pressure gauges in high-heat, non-steam applications

There will be instances when your pressure gauge will come into contact with processes that exceed its temperature limits. To enhance the gauge's longevity and accurate measurements, we recommend one of three heat dissipation accessories for your non-steam applications:

1. Microtube siphons.

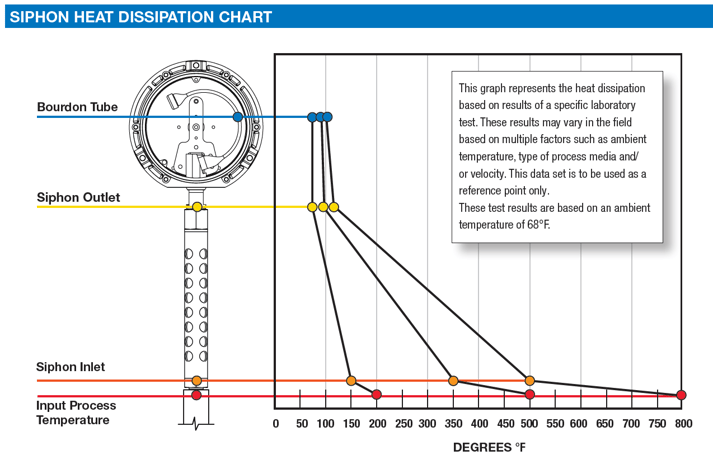

A siphon is a simple, low-cost device used to protect a pressure gauge from high-temperature media and reduce the possible damaging effects of rapid temperature change. It reduces the process media temperature before entering the pressure gauge.

One example is the Ashcroft® MicroTube™ siphon. It has an all 316L Stainless steel construction with a maximum allowable working pressure of 5,000 psi. Having a reduced internal volume, this accessory can reduce temperatures from up to 800 °F (427 °C) and can be used between a pressure gauge and a diaphragm seal.

The microtube style siphon is compatible with many different process media and is designed to protect instruments including pressure gauges, switches and transducers.

Figure 2: Ashcroft® MicroTube™ siphon

Figure 3: Microtube siphon heat dissipation chart

2. Finned siphons

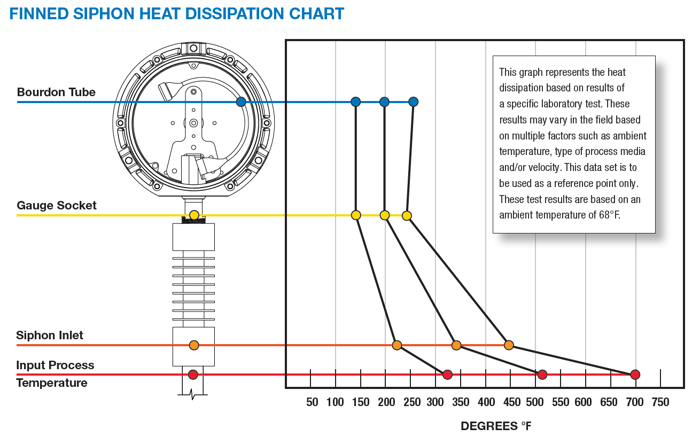

Another accessory that is ideal for heat dissipation is a finned siphon. The fin design increases the surface area exposed to the surrounding environment so it can cool down the fluid before it reaches the pressure gauge.

For example, the Ashcroft® Finned Siphon can reduce temperatures from up to 700 °F (371 °C) and has the capability of containing pressure up to 3,000 psi. The finned siphon is offered in 316 Stainless steel or Monel material and has a compact design with direct mount installation.

This device also features a built-in dampening mechanism to help control the effects of pulsation and dissipate pressure spikes and surges. Like the microtube style, the finned siphon is also compatible with many process media and is ideal for protecting instruments including pressure gauges, switches and transducers.

Figure 4: Ashcroft® Finned Siphon

Figure 5: Finned siphon heat dissipation

3. Capillary lines

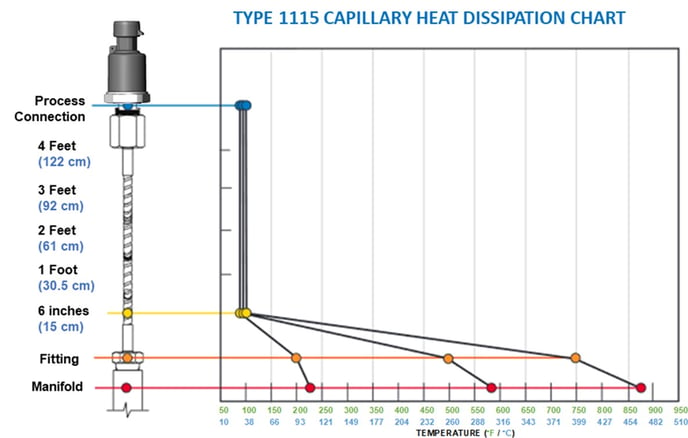

Another accessory that is commonly used for heat dissipation is a capillary line. This dual-purpose accessory can be used when you need to install the instrument away from the process media or a distance from an ambient heat source.

Capillary lines work by minimizing the media volume while maximizing the surface area that is exposed to the surrounding temperature. One example is the Ashcroft® 1115 Capillary Line. It is designed to protect your pressure instrument from high or low temperatures with its wide temperature range of -300 °F (-184 °C) to 750 °F (399 °C). In addition to its temperature range, this accessory also has a maximum allowable working pressure of 10,000 PSI.

Figure 5: Ashcroft® 1115 Capillary Line

The heat dissipation chart below illustrates how as little as 1 foot of capillary can bring the media temperature back down to a safe operating range.

Figure 4: Capillary heat dissipation chart

Ready to learn more?

Now that you better understand the effects temperature can have on your pressure gauge and what accessories are best to use on non-steam applications, you can choose the best protection for your pressure instruments. With a wide range of temperature limits and high maximum allowable working pressures, these simple and inexpensive accessories can make a big difference in the longevity and performance of your pressure gauge and other pressure measurement instruments.

If you want to learn more, here are a few related articles:

- How Does Temperature Affect Pressure Gauge Performance?

- How Does Media Temperature Affect Pressure Transducer Performance?

- What’s the Right Pressure Instrument Mounting Assembly for Me?

- When to Use a Welded Instrument Assembly

- Why Did My Pressure Equipment Fail? 6 Instrument Killers

Contact us today to talk to one of our industry experts and get all your questions answered. In the meantime, download our guide to learn how to avoid pressure equipment failure.

Jessi Jackowski, Product Leader – Diaphragm Seals & Accessories

Jessi Jackowski joined Ashcroft in 2019 as an Inside Sales Specialist before transitioning to the OEM team as a Group Lead. Today, she is the product leader for diaphragm seals and accessories. Prior to Ashcroft, Jessi was the Head Inside Sales Representative for an industrial manufacturer specializing in electrical, automotive, and plumbing tooling. Jessi holds a B.S. in History Education from Southern Connecticut State University. In her free time, she enjoys traveling, spending time with family, and visiting the beach.