By:

Jessi Jackowski

Product Leader – Diaphragm Seals & Accessories

Published on:

April 3rd, 2024

Topics:

Subscribe now and get the latest blog posts delivered straight to your inbox.

How Does Temperature Affect Pressure Gauge Performance?

By:

Jessi Jackowski

Product Leader – Diaphragm Seals & Accessories

Published on:

April 3rd, 2024

Topics:

This article was originally published on February 9, 2022, and was updated on April 3, 2024.

Pressure gauges are often used in challenging environments where they could be exposed to extreme temperatures that may damage them or impact their accuracy.

These extreme temperatures can come from a variety of sources such as the surrounding environment (ambient temperature), or the temperature of the process media being measured (media temperature).

How do you minimize the effects of temperature on your instrumentation and protect your pressure gauges from damage?

Read on to learn the effects that temperature can have on pressure gauges and their performance. Plus, you will gain insights into how you can address these issues to keep your gauge working at peak performance.

Temperature Effects on Pressure Gauges

Pressure gauges are rated for use in a specific temperature range. Using gauges in temperatures outside of their range can lead to damage, depending on their design and construction.

Discoloration of the dial and hardening of the gasket may occur as ambient or process temperatures exceed 150 °F. Non-liquid-filled gauges with standard glass windows can withstand continuous operating temperatures up to 250 °F (121 °C).

Liquid-filled pressure gauges can withstand 200 °F (93 °C) but glycerin fill and acrylic windows will tend to yellow. Gauges with welded joints will withstand 750 °F (400 °C), and those with silver brazed joints will withstand 450 °F (232 °C) for short times without rupture, but other parts of the gauge can be destroyed and calibration lost.

For continuous use and for process or ambient temperatures above 250 °F (121 °C), a diaphragm seal, capillary or siphon is recommended. A standard dry gauge can experience slowed point response time in low temperatures.

Ambient Temperature

Ambient temperature is the air temperature that’s measured around the gauge or instrument. A gauge or instrument that is mounted alongside a heat source like an oven is a good example of where elevated ambient temperature can occur.

Or, if an instrument is mounted outdoors in Siberia in the winter, the instrument can see temperatures to -78 °F (-61 °C). Both extremes should be a call to action to protect the instrument.

Process Temperature

Process temperature is the temperature of the media directly touching the wetted parts of the instrument. With a pressure gauge that includes the process connection, and in most cases, the Bourdon tube and tip.

With an electronic product like a transducer, this usually involves the process connection and the sensing element. Like ambient temperature extremes, temperatures beyond what is recommended by the supplier should be a cue to take action to protect the instrument.

Storage Temperature

You should always adhere to manufacturer storage temperature recommendations. Ashcroft instruments should be stored indoors in a clean, dry, well-ventilated area, avoiding condensation and humidity. Storage temperature limits can range from -40 °F to 250 °F (-40 °C to 121 °C), depending on the configuration.

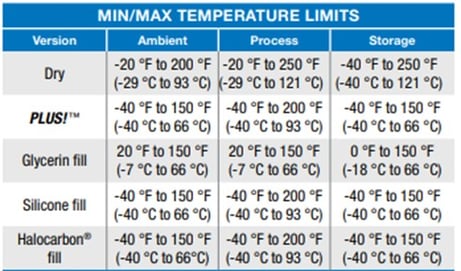

Figure 1 below provides guidance on temperature limits for Ashcroft pressure gauges. Refer to the product datasheet for variances to this.

Figure 1: Minimum and Maximum Temperature Limits.

Temperature Compensation

When high or low temperatures affect pressure instruments, manufacturers may utilize temperature compensation to counteract the effects. This process differs depending on the instrument you are using:

Mechanical Pressure Gauges

Solid front gauges typically provide temperature compensation with a rear elastomeric flexible diaphragm or bladder. This allows for internal case pressure to expand or contract within the gauge.

For solid front gauges with a temperature-compensated diaphragm/bladder, accuracy at temperatures above or below the reference ambient temperature of 68 °F (20 °C) will be affected by approximately 0.4% per 25 °F.

When additional compensation is required, a temperature-compensated movement further reduces temperature error. The temperature compensator reduces errors caused by temperature to less than 0.005% per degree Fahrenheit of temperature change. See the Ashcroft 1082 test gauge datasheet for more information.

View ASME B40.100-2013 for more guidance on sealed gauge cases and temperature error.

Electronic Pressure Instruments

The process of temperature compensation for electronic pressure instruments involves measuring the internal temperature and compensating the output signal to offset the effects of temperature.

In applications where temperature changes take a long time (hours, days) even if they are very large, it is much more likely that a consistent and equalized temperature profile is achieved, and the temperature compensation is working well.

In applications with large changes in media temperature that happen quickly while the surrounding environment stays the same, a variety of solutions can mitigate the extreme temperature effects.

Mitigating Temperature Effects

There are several common solutions for instrument problems stemming from excessively high or excessively low temperatures:

Mounting the Instrument Remotely

You can install the instrument away from the process media or away from an ambient heat source with a capillary to protect it from high or low temperatures. A gauge pipe mounting bracket is a convenient available option when remotely mounting the gauge.

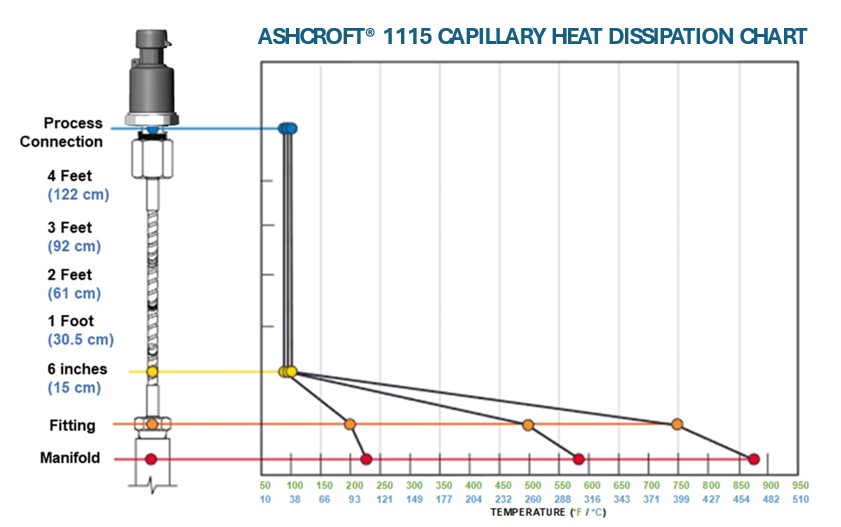

The Ashcroft® 1115 Capillary is rated for temperatures of -300 °F to 750 °F (-184 °C to 399 °C). A simple 5-foot length of capillary between the instrument and the process is very effective at increasing low temperatures and decreasing high temperatures.

A capillary helps lower (or increase) the temperature of the media by minimizing the media volume while maximizing the surface area exposed to the surrounding (ambient) temperature.

A few inches/centimeters can bring the media temperature back to a safe operating range.

Figure 2: The Ashcroft® Type 1115 Capillary Heat Dissipation Chart.

Mounting the Instrument Directly

Often, direct mounting a pressure gauge or instrument is more desirable than remote mounting. Direct mounting eliminates the task of remotely securing and mounting the instrument.

The Ashcroft® MicroTube™ or finned siphon are rigid devices mounted directly to the instrument and the process so there is no need to consider how to mount the instrument if it were remotely mounted. The MicroTube™ siphon has been engineered for process pressures to 5,000 psi and process temperatures to 800 °F (427 °C).

The finned siphon is rated for pressures to 3,000 psi and process temperatures to 700 °F (371 °C). Both devices are good temperature dissipaters.

Coil or pigtail siphons, when attached to the instrument, can curtail temperature in steam applications. A pigtail siphon is used for vertical mounting whereas a coil siphon is used for horizontal mounting.

Prior to installation, the siphon loop needs to be filled with water. The water acts as a barrier to protect the instrument from the elevated temperature and the harmful effects of water hammer, which is typical with steam applications.

Diaphragm Seals

Diaphragm seals or isolators, when required, can also dissipate process temperature.

See Figure 3 below:

Figure 3: Diaphragm Seal Heat Dissipation.

Ready to learn more?

Now that you understand the impact that media temperature can have on your measurement instrumentation, you can research the solution that’s right for your application to help ensure your equipment is protected.

If you want to learn more about pressure gauges or the effects of temperature on your equipment, here are a few related articles to check out:

- How To Identify Your Pressure Gauge and Get the Proper Replacement

- How Does Media Temperature Affect Pressure Transducer Performance?

- How Do I Select the Right Pressure Gauge Range?

- How Often Should I Check the Calibration of My Pressure Gauge?

Feel free to contact us today to talk to one of our industry experts and get your pressure gauge questions answered. You can also check out our pressure gauge selection tool to help you find the best instrument for your needs.

Jessi Jackowski, Product Leader – Diaphragm Seals & Accessories

Jessi Jackowski joined Ashcroft in 2019 as an Inside Sales Specialist before transitioning to the OEM team as a Group Lead. Today, she is the product leader for diaphragm seals and accessories. Prior to Ashcroft, Jessi was the Head Inside Sales Representative for an industrial manufacturer specializing in electrical, automotive, and plumbing tooling. Jessi holds a B.S. in History Education from Southern Connecticut State University. In her free time, she enjoys traveling, spending time with family, and visiting the beach.