Subscribe now and get the latest blog posts delivered straight to your inbox.

What is a hazardous location?

If your job involves the risk of a fire or explosion due to an explosive element that is present, you work in a hazardous location. These environments require strict adherence to safety protocols and regulations to protect both personnel and equipment. Even a small incident in these environments could lead to costly downtime or worse.

Ashcroft is a trusted brand of pressure and temperature instrumentation that can be found in countless hazardous locations across the globe. We have a tremendous amount of experience in developing products that are built to ensure smooth operations and the safety of your team.

In this Understanding the Basics article, you will learn more about hazardous locations, the organizations and standards that govern them, code enforcing authorities, how to prevent explosions and more. Throughout the article, you will also find helpful links and additional resources where you can gain additional knowledge about products and best practices.

What constitutes a hazardous location?

A hazardous location is an area where there is a threat of a fire or explosion because there are flammable substances present. Industries that work in hazardous locations include oil & gas, chemical processing, pharmaceuticals and mining to name a few.

For a fire or explosion to occur, you need to have all three of these components present.

- A flammable material (fuel)

- Air (oxygen)

- An ignition source (high temperature, spark, match, etc.)

If you remove any of the three components, you won't have a fire.

Figure 1. Elements of fire.

What organizations define and enforce the standards for hazardous locations?

The International Electrotechnical Commission (IEC) is responsible for writing the basic standards used globally for defining a hazardous location.

However, there are also regional organizations that define and enforce the standards for specific countries. For example,

- In the United States, the National Fire Protection Association (NFPA) works to prevent injury and death, and property damage that can be caused by electrical hazards. They created the NFPA 70 National Electric Code® (NEC) to serve as a guide that offers best practices for designing, installing and inspecting electrical resources.

- In Canada, the Canadian Electrical Code (CEC) is similar to the NEC and focuses on making safer electrical equipment and ensuring consistent improvements in electrical installations across the country.

Code-enforcing authorities with jurisdiction over specific hazardous locations.

The following authorities are responsible for ensuring any hazardous location installation and all equipment used in the installation meet the requirements before providing their stamp of approval.

- Local inspector

- Insurance underwriter representative

- A municipality authority (fire marshall, building and electrical inspector)

Nationally Recognized Testing Labs (NRTLs) confirm whether equipment can be approved for hazardous locations.

The Nationally Recognized Testing Laboratory (NRTL) program was developed by the Occupational Safety and Health Administration (OSHA) to ensure equipment is safe for use in the workplace. NRTL organizations certify compliance to recognized standards, which are typically based on the NFPA 70.

Examples of NRTL Organizations

- Underwriter’s Laboratories – UL

- Factory Mutual Research Corporation – FM

- Canadian Standards Association - CSA

Each organization tests to the NEC or CEC codes as described above and follows its own test methods to make sure a product is safe for use in its intended environment.

Be mindful that UL, FM, and CSA provide approvals for various safety standards, so it is crucial to determine the specific approval that the instrument holds. The instrument label will clearly indicate any hazardous location approvals and requirements to ensure compliance and safety.

How to tell if your equipment meets all applicable requirements for a location.

As mentioned earlier, every instrument or type of equipment used in a hazardous location must meet very specific requirements for these locations and be marked with its ratings.

Proper labeling indicates to the inspector if the equipment is approved for the specific application. For example, the label below indicates that this instrument is UL-certified (meets local and federal environmental safety regulations) for Class 1 Groups B, C, and D and Class II Groups E, F and G.

Figure 2: Ashcroft® B-Series NEMA 7/9 Explosion Proof Pressure Switch label.

Methods for preventing an explosion or fire.

Removing the ignition source by either containment or limiting the energy is the best way to prevent a dangerous incident from occurring in these areas.

-

Explosion-proof or flame-proof

To be considered explosion-proof, instruments like the Ashcroft® B-Series NEMA 7/9 Explosion Proof Pressure Switch have enclosures with specially designed flame paths that will allow the internal explosion to vent without allowing a flame to escape the enclosure. The flame path has a minimum of 7 threads engaged on the instrument's case cover or conduit connections to be safe. - Intrinsically safe

This means limiting the energy that is applied to an instrument to prevent an explosion from occurring in the first place. You do this by using an approved barrier. The Ashcroft® E2S Pressure Transducer is an example of an intrinsically safe transducer that can be used with a barrier. The barrier creates a buffer between the hazardous location where the transmitter is and the non-hazardous location where your instrumentation and circuit control are located. This is the safest method and is the only method approved for Zone 0 applications (see below).

- Nonincendive

Similar to intrinsically safe, nonincendive also limits the energy applied to an instrument to prevent explosions. However, nonincendive achieves this without the need for a barrier. This method is suitable for use in Division 2 hazardous areas (see below). -

Simple apparatus

These are devices that are unable to generate or store energy, such as a dry-contact microswitch that can be found in Ashcroft pressure and temperature switches. They are suitable for use with an intrinsically safe barrier, as long as long as the barrier has been approved for use with a simple apparatus.

Divisions and Zones are the two systems used to classify a hazardous location.

The Division System is based on NEC 500 codes and includes two Divisions and three Classes, which specify the level of danger.

-

Division 1 is the most hazardous because the hazard (which can be classified as the type of fuel, e.g. flammable gas/vapor, combustible dust or fibers) is present under normal conditions. For example, an underground gas tank, gas tanker truck, and piping on both a tanker and a gas pump are all considered Division 1.

-

Division 2 is less hazardous because there is no danger present under normal conditions but could be present in abnormal situations, such as a shift in the surrounding air.

Figure 3. The Division System divisions and classes.

Figure 4. Division system example.

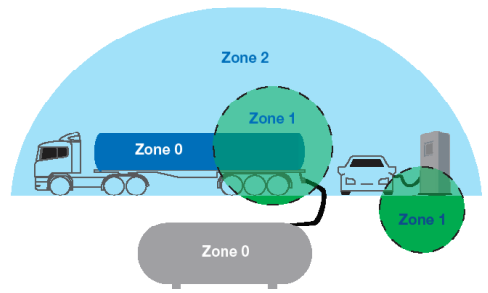

The Zone System is similar to the Division System, but it is based on IEC standards and is used in the NEC505, ATEX and IECEx systems, to name a few.

- Zone 0 is the most hazardous because the hazard (which can be grouped by the specific type of fuel, e.g. methane, coal dust, propane, ethylene, hydrogen/acetylene) is continuously present.

- Zone 1 is an area where the hazard is most likely to occur. An example would be the piping on the tanker truck and the gas pump.

- Zone 2 is an area where the hazard is not likely to occur, for instance, in the surrounding air. In Zone 2, however, while there is no danger present under normal conditions, it could be present in abnormal situations, such as a shift in the surrounding air.

Figure 5. The Zone System zones and groups.

Figure 6. Zone System example.

Ready to go beyond the basics?

Now that you know how we define a hazardous location, the standards you must follow to ensure the safety of your people and your operation, and the precautions you can take to prevent a fire or explosion, you may want to learn more. As a next step, we've compiled a few articles related to the topic for your reference:

- What are safe temperature sensors for hydrogen for hydrogen applications?

- Choosing a pressure gauge for hydrogen applications

- Compliant pressure gauges for sour gas applications

- Why pressure gauges need approvals for LNG and CNG applications

At any time, feel free to contact one of our product experts with any questions you have.

In the meantime, download our e-book to learn how to select the right instruments for hazardous applications.

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.

Topics: