Subscribe now and get the latest blog posts delivered straight to your inbox.

Why Pressure Gauges Need R110 Approvals for CNG and LNG Applications

If you are among the growing number of natural gas vehicle (NGV) manufacturers that use Compressed Natural Gas (CNG) or Liquified Natural Gas (LNG) power-generating components, you know that safety in your process is paramount. That is why it is important to ensure any pressure measurement instrumentation used in these applications has proper approvals from applicable governing agencies.

However, acceptable approvals for cars and trucks in the U.S. are different from approvals you will need for vehicles made for the overseas market. For instance, all NGV vehicles in Europe must follow Regulation No. 110 (R110) safety regulations.

As a recognized leader in pressure and temperature measurement instrumentation for industrial and OEM markets, Ashcroft receives daily questions about the challenges our customers are facing. In this article, you will learn more about CNG and LNG-powered vehicles and why R110 approvals are necessary for any instruments used in the production of NGV vehicles that are sold in Europe.

When you are finished reading, you will also receive additional resources to help you select the best pressure instrumentation to meet your specific needs.

What are CNG and LNG Powered Vehicles?

The shift from gasoline and diesel-powered engines to natural gas alternatives, like CNG for cars and LNG for trucks, represents a significant transition in the automotive and transportation industries. These options are both primarily made of methane, which is more sustainable and environmentally friendly. Here is a closer look at these two options.

1. Compressed Natural Gas (CNG)

CNG is a clear, odorless and corrosion-free natural gas that is less expensive and more efficient than traditional fuel options. Advancements in fuel storage technology are one reason for the rising popularity of CNG vehicles overseas, including sedans, SUVs and pickup trucks. Here are some more reasons this alternative fuel source is gaining traction across the globe:

Cost-effective. CNG is a more affordable fuel choice, making it an attractive option for budget-conscious consumers.

Ecofriendly. CNG is from compressed methane gas that is stored in the vehicle using high-pressure cylinders, making it a cleaner fuel source.

Available refueling stations: The increase of CNG fueling options at traditional petrol and diesel filling stations makes it easier and more convenient for CNG vehicle owners to stay fueled.

How CNG vehicles work.

Like gasoline engines, CNG vehicles have spark-ignited combustion engines. The natural gas is stored in a high-pressure fuel tank and transferred through the system’s fuel lines. A pressure regulator then lowers the pressure to align with the engine's fuel injection system before the fuel enters the intake manifold or combustion chamber. In the chamber, the gas mixes with air, gets compressed, and is ignited by a spark plug.

Risks of CNG vehicles.

Although driving a CNG-fueled car has many benefits, manufacturers must also consider the potential risks associated with CNG engines. One rare but notable risk is fire. Understanding the potential causes of fires in these vehicles is crucial to ensure a safe driving experience for consumers. In addition to extreme temperatures which can cause the fuel to expand or contract and cause a malfunction, there are a few other factors that can cause a fire in CNG-powered engines.

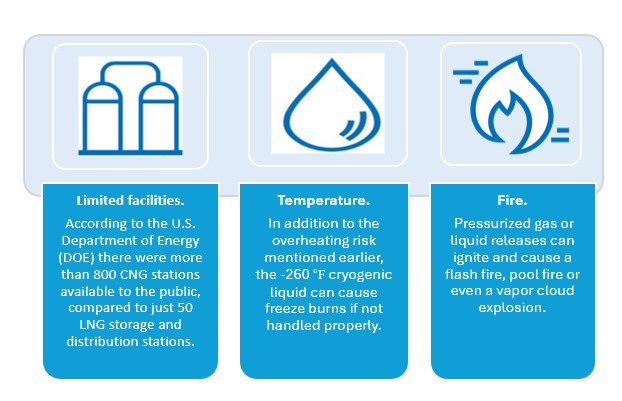

Figure 1. CNG fire risks.

2. Liquified Natural Gas (CNG)

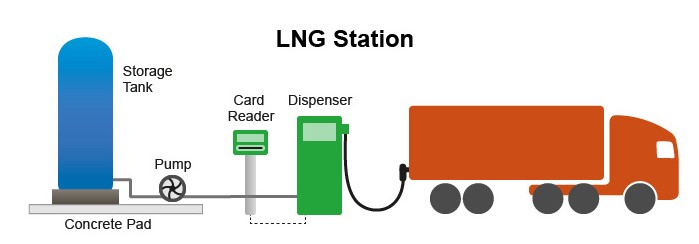

LNG is essentially the same substance as CNG. It is about 90% methane, odorless, colorless and free of corrosion and toxins. The primary difference is that instead of being stored as a gas, LNG is compressed and cooled down to about -162 °C/-260 °F. At that temperature, the gas becomes a cryogenic liquid that is used for LNG-powered vehicles. Due to the dense nature of LNG, an LNG tank can hold more fuel than the CNG tank and enable the vehicle to travel further. For this reason, LNG is a popular option for larger trucks that travel long distances.

Figure 2. CNG storage and fueling station example from the Department of Energy (DOE).

Challenges with LNG.

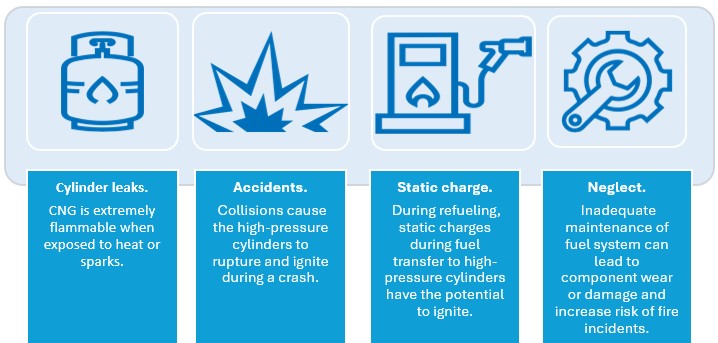

LNG is a complex fuel that needs to be handled properly to avoid risks. One potential risk is overheating. We mentioned earlier that LNG is a cryogenic fuel that needs to be stored at approximately -162 °C/-260 °F. If trucks carrying LNG fuel do not have proper cooling systems, the tanks can get hot causing some of the fuel to vaporize. With no ventilation, pressure builds inside the tank and there is an increased risk of explosion. Here are a few other safety hazards to keep in mind.

What is Regulation No. R110?

R110 refers to the standard safety regulations of the United Nations/Economic Commission for Europe (UN/ECE) regarding the approval of:

- Individual parts that are used in the propulsion system of CNG and/or LNG-powered vehicles.

- Vehicles that install specifically approved components in the propulsion system of CNG and/or LNG-powered vehicles.

For any pressure gauges you use in CNG or LNG engines that will be shipped overseas, R110 approvals are required.

Leaking has the biggest potential to lead to fires. You need a gauge that has been tested to what your application will see in the field. Pressure measurement instruments like the Ashcroft® 8008S Pressure Gauge and the 8009S Pressure Gauge are designed to meet both ASME B40.100 and EN837-1 specifications and have the R110 approval for CNG and LNG applications. They have been tested with natural gas upwards of 400% of scale working pressure. This is key as the gauges were tested with natural gas instead of water or oil and confirmed any wetted part does not contain micro-cracks within the unit as water/oil can seal the crack holding pressure that gas might seep through.

The gauges have been tested for any external leaks while under pressure load. This approval is for gauges used in vehicles that have vibration and assures they can withstand the vibration frequency they might experience. For applications on tanks on land or near the sea, the gauge also goes through salt spray exposure. Having 304 or 316L Stainless steel components allows for good corrosion protection.

Ready to learn more?

With a more solid understanding of CNG and LNG vehicles and the R110 requirements for distribution outside of the U.S., you may still have some questions about Ashcroft’s pressure gauges. Here are a few resources that may help you decide which pressure gauge is the best fit for your application.

- Product Review: 8008S Stainless Steel Pressure Gauge

- 800S Pressure Gauge for Compressed Gas and Other Critical Applications

- Open-Front vs. Solid-Front Pressure Gauges

You can also contact us directly to talk to one of our industry experts and get your pressure gauge questions answered. In the meantime, feel free to download our guide on another alternative energy source, Pressure and Temperature Instrumentation in Hydrogen Systems.

Eric Deoliveira, Business Development Leader

Eric Deoliveira is a Business Development Leader at Ashcroft, Inc. He is responsible for developing industrial and digital instruments, including those designed for sanitary and high-purity applications. Eric has been with Ashcroft since 2015 and spent 3 years as a Product Support Engineer for Mechanical Temperature and 7 years as a Product Manager before transitioning into his current leadership role. Eric enjoys coming up with solutions for customer problems and introducing new products to satisfy the needs of the market. When not working on his products, he is out golfing in the summer and skiing in the winter.

Topics: