Subscribe now and get the latest blog posts delivered straight to your inbox.

What is a Submersible Pressure Transmitter and How Does it Work?

According to the Environmental Protection Agency (EPA), groundwater serves as a crucial resource for half of the U.S. population. Reliance on this vital natural resource is especially significant in regions with scarce rainfall, limited surface water availability, or high agricultural demands and population.

As a leading manufacturer of pressure and temperature instrumentation, Ashcroft understands the challenges of protecting this vital resource. In this article, you will learn about submersible pressure transmitters and how they are used to monitor water levels and provide essential information to water management personnel. You will also see examples of four common applications where submersibles are used and some challenges these instruments may encounter while in use.

When you are done reading, you will find additional, related resources that may be of interest when you are ready to go beyond the basics of this topic.

What is a submersible pressure transmitter?

Threats to our water supply, such as drought, overuse, rising water temperatures and contamination are distressing aquifers and underscoring the importance of monitoring and managing this resource by any means available. Proper control and monitoring of water levels with a submersible pressure transmitter is one way this is done.

A submersible transmitter measures fluid pressure when submerged in liquid. The sealed design, rated IP68/NEMA 6P, enables the transmitter to be fully immersed in water or other liquids without compromising its functionality. It accurately detects and transmits pressure readings from underwater applications, such as tanks, wells, or water treatment facilities, to let operators know how much water is present at a given time.

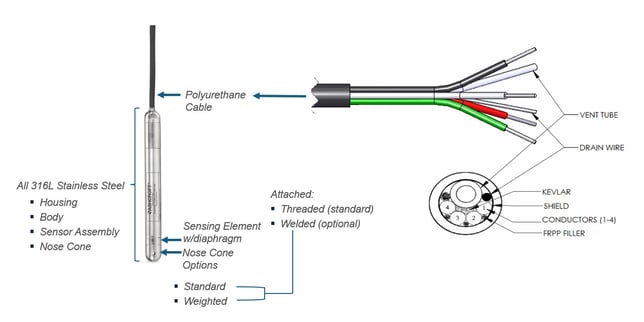

Figure 1. Ashcroft® SL17 submersible pressure transmitter.

How the submersible transmitter works

In the illustration above, you can see where there is a waterproof sensing element with a diaphragm located near the nose cone. The vent tube allows the pressure sensor to be referenced to the atmospheric pressure at the end of the cable so it can measure the height of the water.

How is water depth measured with a submersible pressure transmitter?

The water level is the difference between the depth of the submersible and the measured height of the water column (see Figure 2). The submersible cable is typically marked every foot, so the depth can be measured when it is installed. The submersible measures the height of the water above it. To calculate the water depth you simply subtract the measured water height from the depth of the submersible.

Figure 2. How water depth is measured.

Using a submersible to measure water depth in a production well.

In this type of application, the submersible is installed just above the water pump in the well. (See Figure 3 below.) Space constraints are a common challenge of this application because the instruments are often placed in narrow PVC pipes as small as 1” in diameter. With that in mind, there are some key features to look for in a submersible transducer:

- A narrow profile. This makes installation easier and helps prevent the transmitter from getting stuck in the pipe.

- A weighted nose cone. This added weight of the cone will help guide the transmitter through tight pipes and prevent tangling of the cable. The nose cose can either be threaded or welded to the transmitter.

- A custom-length polyurethane cable. This type of cable material is made in part with Kevlar, which helps prevent the cable from stretching. If the cable can stretch too much, over time, it can affect the long-term accuracy of the instrument.

- A weatherproof junction box (aka termination box). This is used to protect the vented cable from moisture ingress which could affect the accuracy of the readings.

Figure 3. Water depth measurement in a production well.

Other challenges to be aware of when using a submersible transmitter.

Keep in mind that pumps and control systems can be damaged by things like lightning strikes and pump noise. By adding a surge protector to the termination box, your submersible can potentially withstand an energy pulse of up to 500 V or 250 A. However, nothing can withstand a direct strike of lightning. Plus, some submersible transmitters, like the Ashcroft® SL17 offer built-in EMC protection as well as a shielded cable to prevent noise from getting into the control system.

Using a submersible to measure water depth in monitoring wells.

Whenever a well pump is running, a drawdown can occur around the pump. This is also known as the cone of depression. The depth of the cone of depression is very important to monitor and helps prevent the well from running dry. This is done by mounting the submersible just above the pump.

The monitoring well itself is placed near the production well to keep track of the water table level. This is shown on the right side of Figure 4. The information provided by the monitoring well is crucial for operators to be able to observe and record water table depth over long periods. Because of this, the accuracy and stability of the submersible transmitter are vital.

To optimize the instrument's reliability, Ashcroft recommends using a submersible with 0.25% of span terminal point accuracy and 0.25% FS stability per year.

Figure 4. Water depth measurement in a monitoring well.

Using a submersible transmitter to measure vented tank levels in open pit areas.

When you are dealing with a vented water tank in a pit or low-lying area. Because of the potential for flooding, a submersible transmitter with an NPT adapter in place of the nose cone is a great choice for tank-level measurement. In the example below, the submersible is threaded into the flange near the bottom of the tank and the tank level can be seen on the display mounted next to the termination box.

The water in the pit will not affect the output or condition of the transmitter. Also, variations in atmospheric pressure will not interfere with the transmitter's measurements.

Figure 5. Vented tank in open pit.

The submersible is vented through the cable into the termination box and is connected to a desiccant filter. The desiccant filter is used to keep any moisture from getting back into the submersible. This is critical to accurate vented tank level measurement. The filter changes from blue when new, to pink to indicate when it is time to be replaced.

Monitoring leachate in landfills.

Landfills typically use a protective liner to contain the leachate to prevent environmental contamination. In this application, two submersibles are used:

- The first is placed inside the liner. This one monitors the leachate level and makes sure it can be pumped out and filtered as necessary.

- A second submersible monitors the water table outside of the liner. A sudden increase in water level may indicate a breach of the liner.

When considering the possible contaminations in the Leachate, chemical compatibility of the transmitter is important. The submersible should be constructed with a 316L stainless steel body and polyurethane cable. Please review the Ashcroft® Corrosion Guide for information regarding compatibility for your application.

Figure 6. Leachate in landfill.

Ready to go beyond the basics?

Now that you know what a submersible pressure transmitter is, how it works and the common applications where you will find them, are you ready to learn more? Here are a few other basic articles as well as additional helpful resources to help you take the next step in building your knowledge on the subject:

- Ashcroft® SL 17 submersible transmitter - video

- SL 17 submersible level pressure transmitter - webinar

- Tackling the challenge of water level management - webinar

- Pressure Transducer or Pressure Transmitter? The answer depends on the output.

Or, to speak with someone directly, feel free to contact one of our product experts with any questions you have. In the meantime, download our water/wastewater industry solutions guide.

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.

Topics: