Subscribe now and get the latest blog posts delivered straight to your inbox.

4 Important Benefits of Critical Application Instrument Audits

This article was originally published on August 29, 2023, and updated on September 24, 2025.

When your organization operates equipment in critical processes, whether it is dealing with hazardous chemicals or running power stations providing energy for thousands of households, you can’t afford to question the accuracy and effectiveness of your pressure and temperature instruments.

For these critical applications, your pressure and temperature instruments must be dependable and function the way your operators expect. It’s not always enough to perform the normal set of daily checks done by the team. From time to time, you need a more full-scale solution that gives you an in-depth understanding of how your instruments are performing and if improvements are needed.

This is where an instrument audit, like the one Ashcroft offers in our Critical Application Solution Experts® (CASE®) service, could be the perfect solution for helping you. Read this article to learn what’s involved in a CASE audit and the benefits it provides plant managers who pursue one, including keeping your equipment in top condition.

What is an instrument audit, and why perform one?

An instrument audit is a comprehensive process for reviewing and analyzing existing pressure and temperature instruments to ensure they are delivering accurate readings.

Here's what you can expect:

- Insights into the current status and performance of every instrument covered in the scope of the audit

- Comprehensive documentation of instrument conditions and performance

- Recommendations for necessary improvements or adjustments

In the more than 170 years of providing instrumentation solutions for critical applications, Ashcroft has found that there are two key drivers of audit requests from industry supervisors:

1. Safety

They want assurances that the application won't cause harm to any equipment or people on the job.

2. System performance

In critical environments, ensuring every instrument functions accurately and reliably is essential. These audits identify weaknesses so issues can be addressed before they lead to failures.

What are the benefits of a CASE® audit?

A CASE® audit gives you a convenient, all-in-one solution for thoroughly evaluating your instruments. With it, you gain ongoing assurance that your instruments remain reliable and functional well beyond the initial audit. The four aspects to this audit include:

Here's a closer look at each service and how it will benefit you.

1. Instrument range consolidation

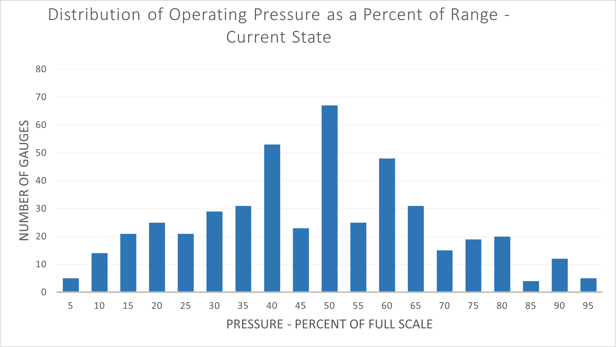

One of the most common instrument challenges we see facilities dealing with is varying ranges across various sets of instruments. For example, you may have installed pressure gauges having a range of 0 to 100 psi when your system was initially constructed, but then needed to use 0 to 300 psi gauges because the correct ranges were not available.

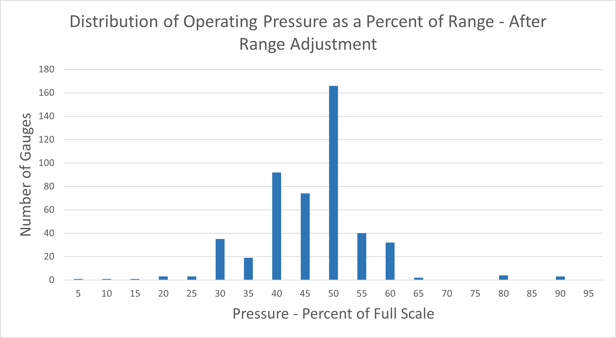

This can quickly create unnecessary complications for your operators and technicians. Stocking multiple ranges makes it harder to select the right replacement and increases the risk of errors in measurement and data recording.

A CASE® audit enables you to standardize your instrument ranges, making data collection more efficient and reducing costs by removing any ranges that are unnecessary for your process requirements.

Figure 1. Pre-audit operating pressure example

Figure 2. Post-audit operating pressure example

2. Failure analysis

Failures are never ideal—especially in critical applications where even minor inefficiencies can have major consequences. When issues occur in your system, you need answers and real solutions. With a CASE® audit, you gain clear insights into the cause of each failure and targeted strategies to prevent repeat problems. You can take advantage of remote diagnostics to confirm performance improvements after the audit, helping you minimize downtime, reduce risk, and keep your system running at peak reliability.

3. Customized process solutions

Instrument calibration is always best performed in situations that are tailor-made for your needs. From weather conditions to system size and power capacity, your pressure and temperature instruments must be calibrated to the kinds of situations they’ll be facing in the real world.

Your audit includes calibration solutions designed for your specific environment, operating conditions and equipment needs. By documenting your process parameters and targeting any problematic gauges, you ensure your instruments are properly selected, maintain calibration longer and stay in service. This reduces unplanned replacements and keeps your operation running smoothly.

4. One-to-many training for your team

For any organization that deals with critical applications, training and certification are always a big concern. Certain members of your team may require permits or licenses that their employer needs to pay for each year. For these companies, it’s much more effective to engage in training for as large a group of people as possible.

When you get a CASE® audit, you enable your entire team to gain critical knowledge on instrument calibration with on-site training tailored to your operations. With everyone trained at once, you streamline certification, reduce costs and ensure consistent best practices across your workforce. Plus, you benefit from ongoing access to CASE® experts, so you always have support when your needs change or questions arise.

Real-world CASE® applications

Wondering what all this looks like when it’s applied during a real audit? Check out two “CASE studies” from previous customers:

- CASE study 1 explains how our gauge assembly recommendations for a customer with a hydrofluoric acid (HF) alkylation unit helped them create a system to detect and resolve acid leaks

- CASE study 2 shows how we worked with a petrochemical refinery customer to diagnose 17% of their gauges as damaged during our initial audit, then upgrade their instrument technology to reduce gauge inventory by 50%.

Is a CASE® audit right for you?

You invest significant time and resources into instrument calibration, so you deserve confidence that your equipment will perform reliably. When you work with an outside expert for your audit, you solve problems at the source—instead of relying on temporary fixes or unnecessary replacements. Whether you’re expanding your system, relocating, or addressing performance challenges, you gain clear insight and lasting improvements that protect your process safety and efficiency for the long term.

Ready to learn more?

If you would like to deepen your knowledge about pressure instruments, here are a few other articles that may interest you.

- Solid Front vs. Open Front Pressure Gauges

- How To Identify Your Pressure Gauge and Get the Proper Replacement

- How Does Temperature Affect Pressure Gauge Performance?

- How Do I Select the Right Pressure Gauge Range?

- Why Did My Pressure Equipment Fail? 6 Instrument Killers

Feel free to contact us today to talk to one of our industry experts and get your questions answered. In the meantime, you can request an Ashcroft CASE® Audit or download our guide to learn how to prevent pressure equipment failure:

Bob Pierce, Territory Sales Manager

Bob Pierce is the Territory Sales Manager (Channels/Distribution), responsible for 6 states in the Southeast Gulf Coast region. He started his career at Ashcroft in 2018 with 25+ years of experience in the fields of Instrumentation and Control Valves. Bob has a Bachelor of Science degree in the School of Business from the University of Alabama – Birmingham.