Subscribe now and get the latest blog posts delivered straight to your inbox.

Choosing the Right Microswitch for your Pressure Switch Application

This article was originally published on August 15, 2022, and updated on May 19, 2025.

Pressure switches are essential components in a wide range of industries and applications. From maintaining safe operation in burners and boiler systems and monitoring hydraulic pressure in industrial machinery, to controlling pump systems in water treatment facilities and ensuring safety in chemical and petrochemical equipment—pressure switches are everywhere.

However, be aware that various factors can affect the performance of your pressure switch in certain applications. Selecting the appropriate microswitch is a minor yet crucial step to guarantee consistent and accurate readings.

Read this article to learn about the different microswitch options available and the applications for which they are best suited. You will also see links to additional resources that can help deepen your knowledge about pressure switches and how they are used.

What is a microswitch for pressure switches?

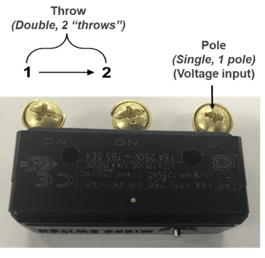

A microswitch is the element inside of pressure switches that turns the switch on or off. You can find them as single pole double throw (SPDT), meaning it has one “arm” that can go left or right for open contact or closed contact.

Figure 1: Single Pole Double Throw Switch

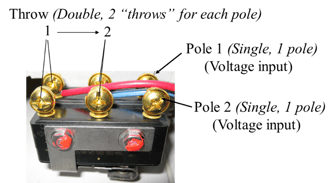

You may also combine two of them to have a switch that acts as a double pole double throw switch (DPDT). This is useful if you need to switch between two different electrical loads.

Figure 2: Double Pole Double Throw Switch

Factors to consider for selecting a microswitch for your pressure switch

There are several factors to consider when selecting the right microswitch for pressure switch applications.

Pressure switch electrical ratings

If a microswitch is used incorrectly or overloaded, it may fail prematurely. This can result in the microswitch burning open, causing a break (no switch action), or the contacts can become welded together, causing a short circuit.

Before you choose the microswitch, ask yourself:

- Is it using alternating current or direct current (AC or DC)?

- What is the voltage and current?

- Is it inductive (as in most industrial applications like pumps or motors) or resistive (like lightbulbs or alarms)?

Different switches have different limits for how much electrical current they can handle, and you need these elements to match to ensure the proper operation of your application.

Pressure switch deadband

Deadband is the difference between the switch's setpoint (the pressure at which the pressure switch activates) and the reset point (the pressure at which the pressure switch deactivates). It is commonly expressed in psi measurement units but is directly related to the travel of the microswitch plunger.

While the set point of the switch can be set at the factory, it can also be calibrated or adjusted by the end user.

Figure 3. Pressure switch deadband

Other factors for choosing a microswitch

- Hermetically sealed microswitches. These options have lower current ratings and are good for environmental ratings (for use in corrosive atmospheres)

- Heavy duty AC/DC switches.

- High-temperature environments.

- Switches with a manual reset. This is useful in applications such as furnaces, so it stays off until it’s repaired and manually started back up.

Microswitches with gold contacts vs. microswitches with silver contacts

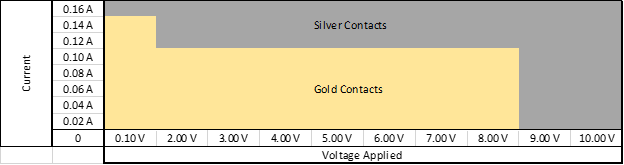

Microswitches are also available with silver and gold options, depending on the application. Standard microswitches have silver contacts, but if the application has low currents such as being connected to a PLC and low voltages, the microswitch should have gold contacts.

The chart below gives a reference for when to choose gold or silver contacts:

Figure 4: When to Use Gold or Silver Contacts

Ashcroft microswitch options

Ashcroft® B Series switches offer multiple microswitch options. These can be used for applications including offshore oil rigs, chemical and petrochemical plants, pulp and paper mills, steel mills, power plants, water and sewage treatment plants and other corrosive environments.

Ready to learn more?

Now that you better understand microswitches and what types are available for different applications, you can choose the best solution for you. Just remember not to mismatch your microswitch with your application’s electrical load because it could cause premature failure of your pressure switch.

The following resources can provide more in-depth information about pressure switches and other factors to consider when selecting the best one for your specific application.

- What is a Pressure Switch?

- Class and Division Codes on Explosion-Proof Pressure Switches

- When Should You Use an Electronic Pressure Switch?

- Choosing a Pressure Switch: 9 Factors to Consider

- What is SIL Certification for Pressure Switches?

- Pressure Switch Basic Calibration Video

If you have more questions, contact us to talk to one of our industry experts. In the meantime, download our guide to learn about pressure switches for chemical and petrochemical applications.

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.

Topics: