Subscribe now and get the latest blog posts delivered straight to your inbox.

Can You Safely Remove a Pressure Instrument from an Isolator?

This article was originally published on May 15, 2023, and updated on May 5, 2025.

For certain applications in water/wastewater and other industries, pressure instruments such as gauges, switches, and transmitters are susceptible to clogging and corrosion. At Ashcroft, we understand that exposure to these conditions can damage the instrument, which can lead to inaccurate measurements and jeopardize the safety of your operation.

Isolators, such as isolation rings, are designed to protect instruments from damage caused by clogging due to large slurries. Diaphragm seals, on the other hand, are used to protect instruments from chemicals like sodium hypochlorite, sodium fluoride or chlorine.

However, removing the instrument from the isolator in the field can be hazardous. Read this article to learn the dangers and discover one way you can perform this task safely.

How isolators protect your pressure instruments

Diaphragm seals and isolation rings function similarly by forming a sealed barrier between the process media and the pressure instrument. Here's how they work:

- Instruments are mounted to the isolator, creating a closed system that uses a fill fluid to transmit pressure from the process to the sensing element without direct contact.

- The filling process first involves pulling a complete vacuum through the fill port to eliminate all air and moisture. Then, a transfer fluid—typically silicone or another specialized fluid—is precisely introduced to ensure accurate pressure transmission.

- Once filled, the assembly must be calibrated—either at the factory or by an authorized assembler—since the isolator can affect the instrument’s original calibration.

- After the filling and calibration are complete, the instrument isolator assembly is ready for installation into the process system.

At this stage, the instrument should remain securely attached to the isolator. Even adjusting its position can affect the accuracy of the calibration. If removal is necessary, the entire assembly must be refilled and recalibrated by the manufacturer or an authorized assembler to ensure proper performance.

The importance of proper pressure instrument removal

Removing a pressure instrument from its isolator is not a routine task—it must be done carefully to preserve system integrity and ensure measurement accuracy. Improper removal can lead to loss of fill fluid, trapped air, contamination, and ultimately, inaccurate pressure readings or instrument failure.

That said, removal is sometimes necessary. Common reasons include:

- Instrument damage (e.g., due to overpressure, vibration, or environmental exposure)

- Scheduled calibration or preventive maintenance

- Suspected performance drift in critical measurement applications

Isolator design considerations and system impact

Many diaphragm seal assemblies are built with a continuous duty design, which allows the instrument portion to be removed while leaving the bottom housing installed in the piping. While convenient, this procedure exposes the process piping, meaning the system must be safely shut down and depressurized before disassembly.

Isolation rings, on the other hand, pose greater challenges:

- Isolation rings are often flanged or threaded directly in-line, making removal more complex.

- Larger rings, especially in industrial or wastewater applications, may require heavy-duty lifting equipment like cranes to uninstall.

- Once removed, the ring must be thoroughly cleaned and sanitized to prevent contamination—an effort that can be both labor-intensive and costly

Calibration and NIST Standards

After removal, the entire instrument-isolator assembly should be sent to a certified facility for refilling and recalibration. The work must be performed by the manufacturer or an authorized service provider that follows standards traceable to SI units through NIST or equivalent national metrology institutes (NMI). Doing so ensures that calibration results are linked through documented, unbroken chains of measurement comparisons back to nationally recognized reference standards. This provides:

- High measurement accuracy

- Consistency across instruments

- Compliance with regulatory and quality standards

Safe and easy pressure instrument removal is available

As described above, removing pressure instruments from isolation systems is often a complex and risky task. But more and more new plant installations and additions to existing plants require instruments with a more efficient solution.

At Ashcroft, our isolation ring assemblies offer a Safe Quick Release™ (SQR™) option that provides a safer, cleaner and more efficient solution for many applications.

What is the SQR™?

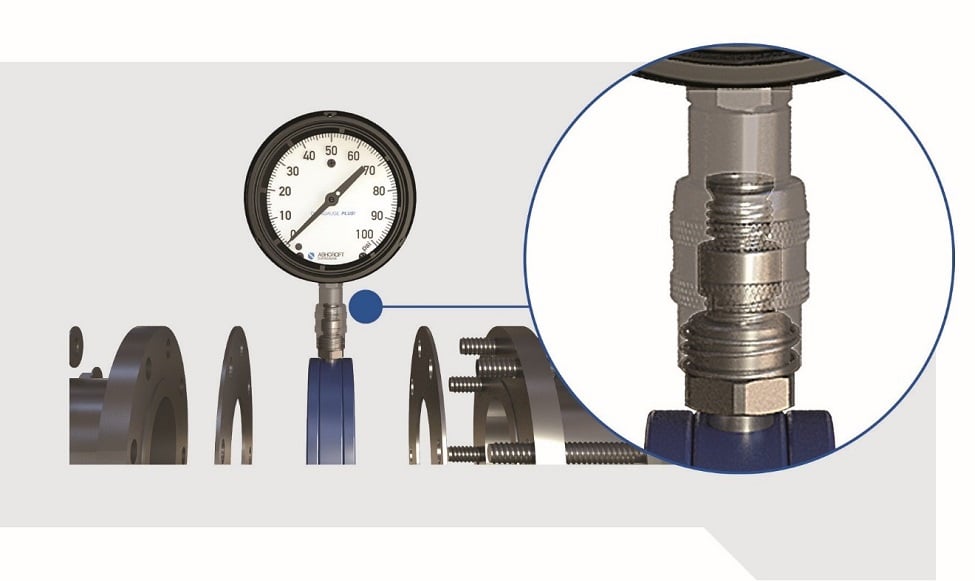

The Safe Quick Release™ is a dry break connector that allows operators to disconnect the instrument from an isolation ring without losing the internal fill fluid. This prevents contamination, reduces maintenance time, and eliminates the need to disassemble surrounding process piping. The release mechanism is built directly into the isolation ring itself, making it simple to operate in the field. Watch a quick video to see how it works.

Key Advantages

- No loss of fill fluid during removal

- No need to break pipe connections, minimizing downtime and complexity

- Improved safety by reducing exposure to process media

- Reusable connection, enabling repeated removal and reinstallation without degrading system performance

Applications and plant integration

The SQR™ option is becoming increasingly popular in new plant builds and plant expansion projects, where maintenance accessibility and process reliability are key design priorities. Because isolation rings typically contain more fill fluid and are more forgiving to volume changes, they can accommodate multiple removal cycles using SQR™ without compromising performance.

Compatibility considerations

While the SQR™ works exceptionally well with isolation ring assemblies, it is not recommended for diaphragm seal systems. Diaphragm seals are highly sensitive to fill volume and mechanical positioning—any disconnection or repositioning can significantly alter the calibration or compromise measurement accuracy.

Fortunately, diaphragm seals are usually easier to remove from the process piping, and they do not present the same logistical challenges as large, inline isolation rings.

Figure 1: Ashcroft® Safe Quick Release™ Option

Ready to learn more?

Now that you better understand the dangers behind removing a pressure instrument from a diaphragm seal or isolation ring assembly, you can help protect your instruments and keep your application running efficiently. If you are interested in discovering more about isolators and how they work with pressure instruments, here are a few articles for your reference:

- When to Use a Diaphragm Seal vs. an Isolation Ring

- Isolation Ring Assemblies for the Water/Wastewater Industry that are Accurate and Reliable

- When Not to Use an Isolation Ring

- Best Practices for Installing Flanged Diaphragm Seals

Feel free to contact us with any questions or concerns. In the meantime, download our guide to choosing the right instrument assembly.

Darren Lewandowski, Territory Sales Manager

Darren Lewandowski is the Territory Sales Manager (Channel/Distribution) at Ashcroft, responsible for the Northeast U.S., from Maine to Maryland. He started his career at Ashcroft in 2018 with 16 years of experience with flow control and measurement. He currently works with distributors and their end users in many areas, these include water/wastewater, food and beverage, high purity, and pharmaceutical to name a few, with a focus on providing solutions. In his leisure time, Darren enjoys traveling with his wife of 27 years, and proudly watching his daughters grow up to be wonderful and accomplished young women.

Topics: