By:

Mark Zabawa

Director of North America OEM/Direct Sales

Published on:

August 27th, 2025

Subscribe now and get the latest blog posts delivered straight to your inbox.

Choosing the Right Pressure Sensor: 5 Factors to Consider

By:

Mark Zabawa

Director of North America OEM/Direct Sales

Published on:

August 27th, 2025

Pressure sensors are a critical part of any hydraulic, HVAC or industrial process system. When specified correctly, these instruments can ensure safe operation, accurate performance and long equipment life. The wrong pressure sensor, however, can lead to inaccurate readings, process inefficiencies, equipment damage, or operator safety risks.

While sensing technology will ultimately dictate what sensor is best for your application, the following factors also need to be considered. By understanding them, you can avoid common pitfalls and protect your system’s integrity. At Ashcroft, we’ve helped engineers and OEMs navigate these challenges for decades.

Read this article to learn:

- The five essential factors to consider when selecting a pressure sensor

- Why media compatibility, hydraulic shock and reference type matter

- How accuracy definitions differ and what to look for

- The role of interchangeability in long-term system reliability

You will also see links to additional resources that can help deepen your knowledge about pressure sensors even more.

1. What materials should you consider for your pressure sensor?

Choosing the right materials is essential to protecting your sensor from failure. The wetted material you choose must be compatible with your process media. Otherwise, instrument damage can occur over time, leading to inaccurate measurements and potential instrument failure. For example, you wouldn’t specify the same wetted material for a low-pressure sensor as you would for a high-pressure application. Each environment demands a different combination of process compatibility, construction requirements and material properties to maintain sensor integrity and dependable performance.

Use Ashcroft's online material selector tool to identify compatible materials for your application.

2. How does hydraulic shock affect sensor performance?

When we think of shock, it’s often in terms of mechanical stress to equipment or a sensor, which is typically addressed in product datasheets. But in fluid systems, hydraulic shock (or water hammer) is the bigger concern. It occurs when fluid velocity changes suddenly, creating a rapid pressure surge. These spikes can be many times higher than normal operating pressure, often faster than a sensor can register, and can permanently damage the diaphragm or sensing element.

If not managed, hydraulic shock may appear as an overpressure failure, with indications such as zero-output offsets or complete diaphragm rupture. To ensure long-term sensor reliability, it’s important to anticipate whether these conditions exist in your system and address them through design choices or protective accessories.

In addition to sensor design and technology calibration, there are several accessories and instruments available to help address these negative process effects, including:

- Pressure snubbers: Uses a porous element to smooth out rapid pulsations.

- Pulsation dampeners: Absorbs surges with a chamber that slows fluid movement.

- Capillary lines: Adds length/volume to buffer fast changes before they reach the sensor.

3. Which pressure reference do you need: gauge, absolute, or differential?

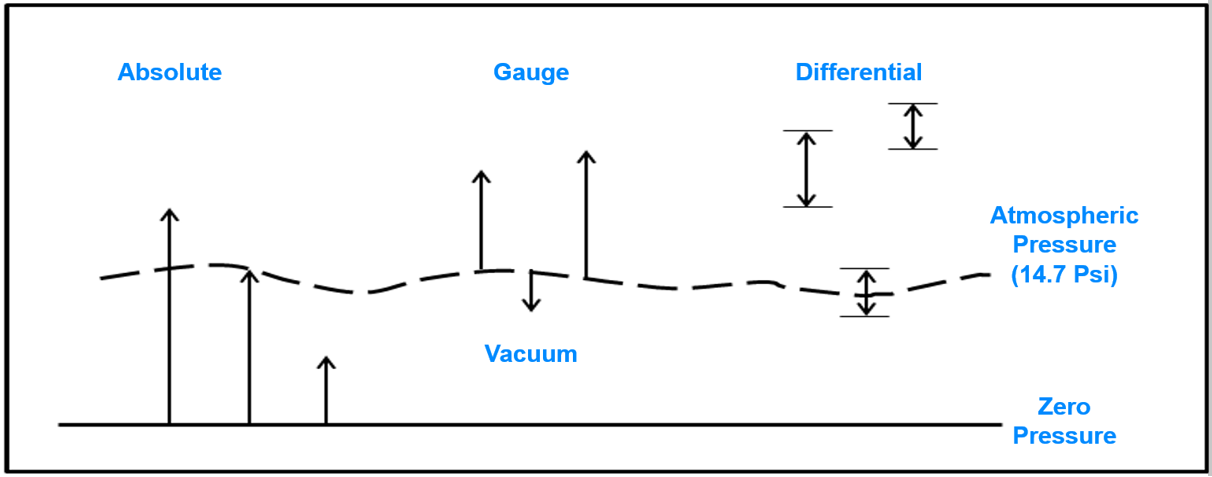

Every pressure measurement requires a reference point. This is the first step in determining which pressure sensor technology can be used in a design. Selecting the wrong reference type results in completely inaccurate readings.

Your pressure reference is particularly important when trying to measure below atmospheric pressure conditions while determining the amount of vacuum. It is critical to know whether the measurement is relative to the atmospheric condition or absolute zero pressure. Here's a quick look at the different reference points:

- Gauge (G): Measures relative to atmospheric pressure, including vacuum ranges.

- Absolute (A): Measures relative to zero pressure (full vacuum).

- Differential (D): Measures the difference between two points.

Figure 1. Different pressure reference points.

4. How accurate does your pressure sensor really need to be?

Accuracy is defined differently by each manufacturer, so a sensor labeled ±0.25% from one brand may not perform identically to another. This inconsistency is sometimes referred to as “Specmanship” due to the lack of universally accepted standards for accuracy.

Key accuracy types commonly referenced include:

- Best Fit Straight Line (BFSL). Measures accuracy as the maximum deviation from an ideal straight line drawn through the sensor's output curve.

- Root Sum Square (RSS). Calculates total accuracy by combining individual error components (such as linearity, hysteresis and repeatability) using a statistical method.

- Terminal or End Point. Defines accuracy by measuring the maximum deviation between the sensor output and the theoretical value across the specified range using the endpoints of the calibration curve.

- Total Error Band (TEB). Accounts for the combined effects of all errors, including the influence of temperature changes and long-term drift, providing a true “worst case” accuracy.

- Typical. Reflects the value most sensors are expected to meet under normal conditions, rather than a guaranteed minimum or maximum value.

When evaluating sensor performance, also consider whether zero and span output offsets are included in the stated accuracy, as well as if temperature variation effects are factored into the published specifications. For example, in critical applications, it may be important that zero and span output offsets be included in accuracy, as the two can add up to an additional ±2% of inaccuracy in some products. Or, if the application is exposed to a wide operating temperature range, make sure the accuracy statement includes the effects of temperature over that range.

5. Why does pressure sensor interchangeability matter in the field?

When replacing a pressure sensor in the field, true system reliability depends on more than swapping one device for another. If zero and span offset errors aren’t included in a manufacturer’s published accuracy statement or aren’t addressed at installation, your system may not perform as originally specified. These discrepancies can result in inaccurate measurements, unexpected downtime or failure to meet process requirements.

Ashcroft addresses this challenge by including zero and span errors in our accuracy specifications. This ensures any replacement delivers the same performance standards as the original, allowing you to maintain system integrity and avoid costly surprises. That's why you should always confirm that your replacement sensor matches both technical criteria and accuracy statements.

Figure 2. Impact of zero/span offset specifications

| Specification Type | Impact in the Field |

|---|---|

| Includes zero/span Offset | Replacement sensor matches original performance without recalibration. |

| Excludes zero/span Offset | Replacement may introduce error, requiring recalibration or causing long-term drift. |

Ready to learn more?

Now you know choosing the right pressure sensor is about more than range or price. It’s about ensuring safe, reliable and accurate performance over the life of your system. By paying close attention to material compatibility, protection against hydraulic shock, the correct pressure reference, accuracy definitions and long-term interchangeability, you can avoid common pitfalls and keep your equipment operating as designed.

If you want to learn more about pressure sensors, here are a few more articles that may interest you:

- What are the Advantages of Ashcroft Pressure Transducers

- How Much Do Pressure Transducers Cost? (6 Factors Impacting Price)

- Understanding Absolute, Vacuum and Compound Pressure

Contact us to speak with one of our industry experts and get your questions answered. In the meantime, download our guide to learn more about the accuracy of your pressure instruments.

Mark Zabawa, Director of North America OEM/Direct Sales

Mark Zabawa is the Director of North America OEM/Direct Sales here at Ashcroft. He has spent the past 25+ years in the pressure sensor/transducer industry, with 15 of those years at Ashcroft. Mark has been in roles ranging from Technical Support and Product Management to Regional and National Sales, and his current role is focused on OEM Direct Sales.