By:

Dave Dlugos

Product Technical Leader

Published on:

February 14th, 2024

Subscribe now and get the latest blog posts delivered straight to your inbox.

How is temperature measured?

By:

Dave Dlugos

Product Technical Leader

Published on:

February 14th, 2024

All industrial applications use some kind of temperature instrument to ensure process temperatures stay within an acceptable range. Choosing the right device can help protect your equipment and your operators from extreme temperature shifts. However, the type of instrument you use will depend on many factors, including the temperature limits of the operation and the instrument, the required output and more.

As a global leader in temperature and pressure instrumentation, Ashcroft created this article as a high-level overview of industrial temperature measurement options. If you are an industry novice or just want a refresher on the basics, this can serve as a good reference piece.

Read on to learn about the different types of industrial temperature instruments, how they work, where they are used and why you might choose one over another. When you are done reading, you will find additional resources related to temperature measurement that may interest you.

Five types of temperature instruments

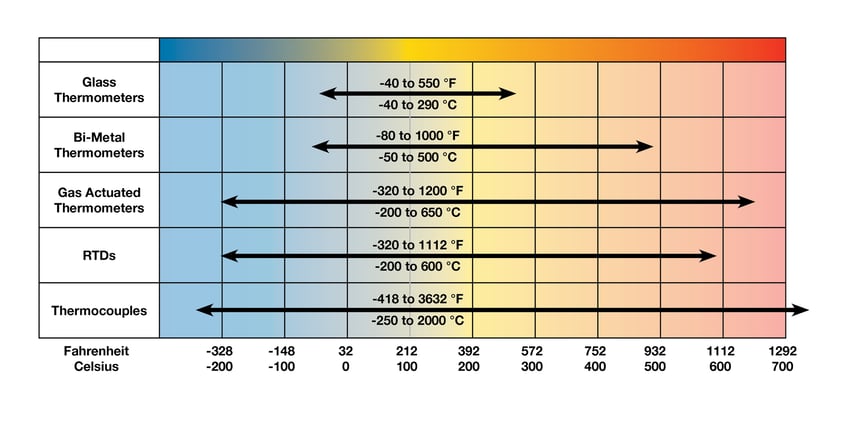

Industries that need to measure process temperature typically select one of five types of instruments to do the job. Three of the five options (glass, bi-metal and gas-actuated thermometers) provide a visual-only display on the dial, while the remaining two (RTDs and thermocouples) will send an electronic signal to a control system in a different location. With each option, you have a specific area of temperature you can monitor.

Glass thermometers. These are the most basic temperature measurement instruments available for industrial applications.

How they work:

- The liquid in the glass of these instruments will expand or contract to the temperature allowing you to read the level of liquid against the scale.

- They are commonly used for a narrow temperature band of – 40 °F to 550 °F.

Figure 1: Glass thermometer.

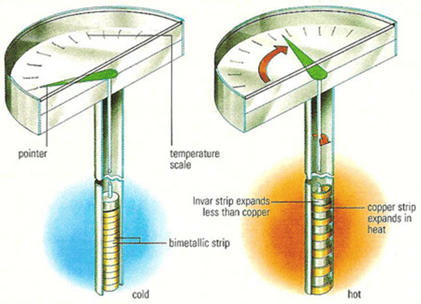

Bi-Metal thermometers. This option uses a bi-metal strip that is built into the mounting stem of the thermometer. The stem can be up to 60” in length.

How they work:

- As the temperature increases, the bi-metal strip expands with the heat and twists causing the dial pointer to move. Since the pointer is directly connected to the shaft, no other mechanics are required to drive the dial on the scale work.

- This option offers a wider range than glass thermometers and can read temperatures from -80 °F to 1000 °F. However, this option is not intended for continuous use beyond 800 °F.

- These thermometers are mounted in the thermowell in the process, offer accurate, reliable and easy-to-read measurements, and should be hermetically sealed to prevent fogging.

- Some thermometers are offered with liquid fill, customized dial printing and a silicone-dampened coil to reduce pointer flutter on high-vibration applications.

Figure 2: Bi-metal thermometer.

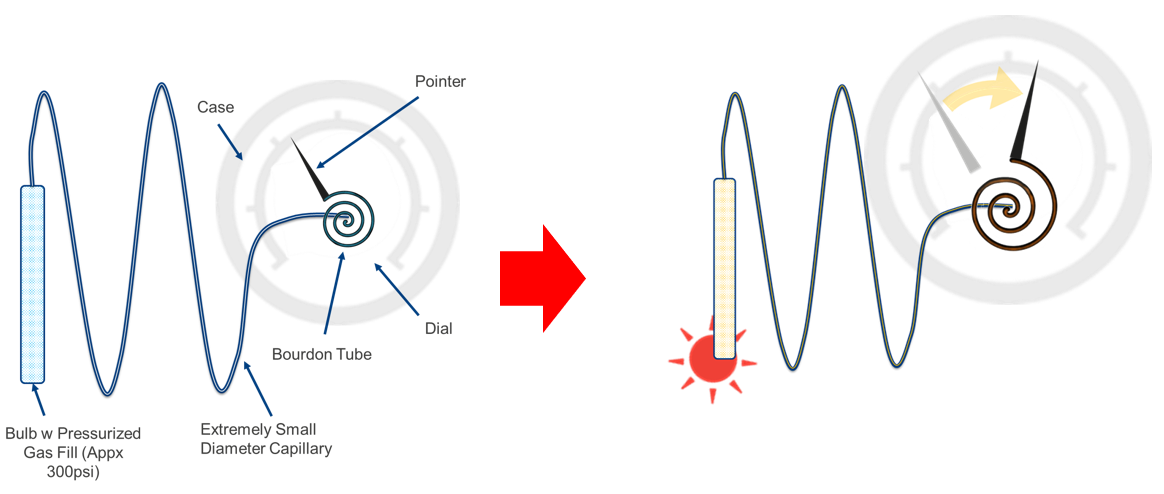

Gas-Actuated thermometers. These thermometers are designed with a bulb that is pressurized with a gas fill (approximately 300 psi). As the temperature increases at the bulb, the gas expands which increases the pressure inside the system.

How they work:

- Inside the thermometer is a component called a bourdon tube. The tube straightens in response to the change in temperature, rotating the pointer, which can be read as temperature against a calibrated dial.

- Like bi-metal thermometers, gas-actuated devices have a direct-drive system with the temperature moving the pointer, but this time with gas pressure using a bourdon tube.

- This instrument can measure extreme cold (-320 °F) to extreme heat (1200 °F).

- Gas-actuated options also resist shock and vibration, have no head or elevation error, are hermetically sealed to prevent fogging, and can be direct-mounted in a thermowell in the process or remotely mounted using a capillary.

Figure 3: Gas-actuated thermometer - how it works.

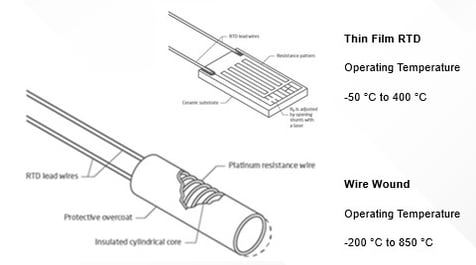

Resistance Temperature Detectors (RTDs). This type of temperature measurement instrument is a sensor that provides an electronic signal of the process temperature which can be sent to the control system or locally indicated using a transmitter that has a display.

How they work:

- As the temperature in your application changes, the resistance of the RTD element also changes.

- The RTD is made using either a thin film or a wire wound circuit.

- RTDs are known for their highly accurate and repeatability measurements, which are a little bit narrower in temperature range than thermocouples.

- The electrical output can be resistive or be converted to a 4-20 mA signal and sent to a control system for remote readings.

- They can also have a visual display using a transmitter for local indication.

Figure 4: Thin film and wire-wound RTD.

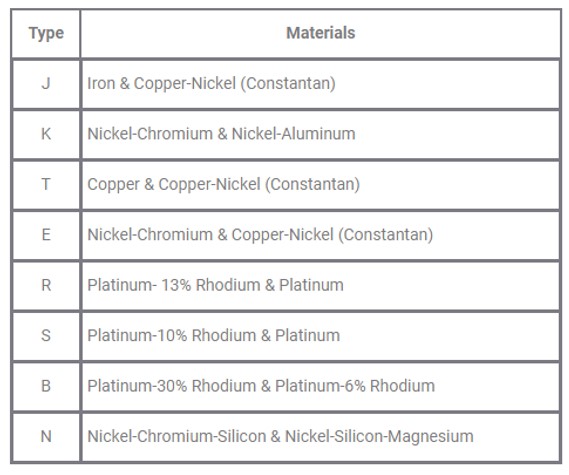

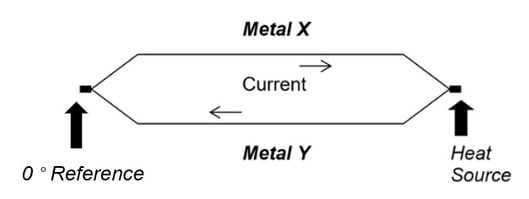

Thermocouples. Like RTDs, thermocouples are sensors that monitor temperature in industrial, process and hazardous installations and send an electronic signal to the control system.

How they work:

- A thermocouple has two wires, each with a different type of metal.

Figure 5: Thermocouple metal options.

- When the two dissimilar wires are joined together at both ends and temperature is applied to one of the junctions, a continuous electrical current will flow through the loop formed by the two wires, producing a measurable voltage.

Figure 6: Thermocouple junctions.

- As the temperature of the source varies, so will the voltage.

- The voltage level is a function of the junction temperature compared to the reference temperature (0 °C), which is referred to as cold junction compensation.

- Thermocouples offer the widest temperature range of all the options (-250 °C - 2000 °C).

Figure 7: Instrument temperature ranges.

Go beyond the basics.

Now that you have a basic understanding of temperature measurement instruments and how they work, are you ready to delve in a little deeper? Here are a few related articles that can get you started.

• Gas-Actuated Thermometers: When to Use Them

• When to Use an RTD vs. a Thermocouple Temperature Sensor

• How Does a Thermocouple Work?

To see how many of these temperature instruments are used, download our guide. Or, feel free to contact one of our product experts with any questions you have.

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.