Subscribe now and get the latest blog posts delivered straight to your inbox.

When to Use an RTD vs. a Thermocouple Temperature Sensor

This article was originally published on September 6, 2022, and updated on July 7, 2025.

When working with critical processes in power generation, chemical manufacturing or food processing, one of your primary challenges is ensuring accurate temperature measurement. The wrong sensor could lead to reduced performance, safety concerns or even equipment failure. That’s why selecting the correct temperature sensor for your application is so important.

As a recognized leader in pressure and temperature measurement instruments, Ashcroft has been helping industries worldwide make informed decisions for over a century. In this article, you will learn about two types of temperature sensors, how they work and their respective advantages and disadvantages. You will also receive guidance on selecting the most suitable sensor for your specific needs.

What is a temperature sensor?

Unlike thermometers, which only display the process temperature visually, temperature sensors actively detect changes in process temperature and convert these changes into output signals. These signals are transmitted to control systems, allowing operators to efficiently monitor and respond to any process variations.

Two commonly used temperature sensors are Resistance Temperature Detectors (RTDs) and thermocouples. These devices can be used in a variety of applications, including the examples in the chart below:

Figure 1: RTD and Thermocouple Application Chart

Using an RTD Temperature Sensor

RTDs, or Resistance Temperature Detectors, use a resistor that changes its electrical resistance as the temperature changes. This relationship allows the RTD to accurately measure temperature. There are two common RTD designs:

- Thin film RTDs feature a resistive element deposited onto a ceramic substrate, making them compact, cost-effective, and ideal for applications requiring fast response times.

- Wire-wound RTDs, on the other hand, use a fine platinum wire coil embedded in a ceramic or glass core, offering superior accuracy and stability across wider temperature ranges.

Figure 2: Thin Film and Wire Wound RTD.

RTDs offer high accuracy and long-term stability, making them ideal for applications requiring precise temperature measurements within a limited range.

RTD Wire Configurations

There are several RTD configurations, including 2-wire, 3-wire and 4-wire.

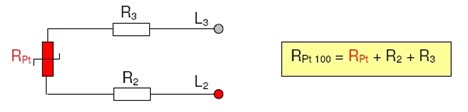

The 2-wire RTD configuration is the simplest among RTD circuit designs. A single lead wire connects each end of the RTD element to the monitoring device. The total circuit resistance includes the lead wire resistance. This is the least accurate of the configurations.

Figure 3: 2-Wire RTD Configuration.

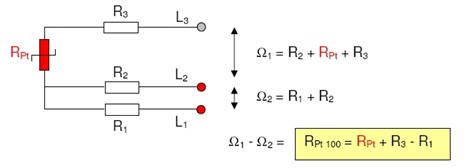

The 3-wire RTD configuration is by far the most common RTD circuit design used in industrial processes. This configuration has two wires connected to one side of the sensing element and one wire connected to the other side. This configuration nulls the lead resistance of the two wires connected to the side of the element, which increases the measurement accuracy.

Figure 4: 3-Wire RTD Configuration.

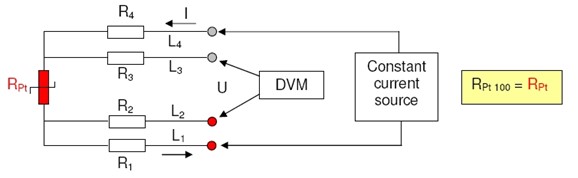

The 4-wire RTD configuration is more complex and more expensive but produces the most accurate results. Two wires connect the sensing nulling the lead resistance on both sides of the sensing element.

Figure 5: 4-Wire RTD Configuration.

Using a Thermocouple Temperature Sensor

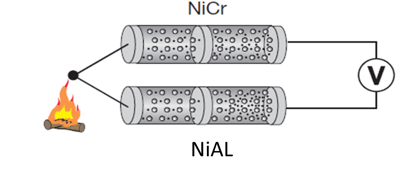

Thermocouples are made of two dissimilar metal wires joined at one end to form a measurement junction. This junction produces a voltage directly proportional to the temperature difference between the measurement point and the reference junction at the opposite end, which is typically connected to a measuring device.

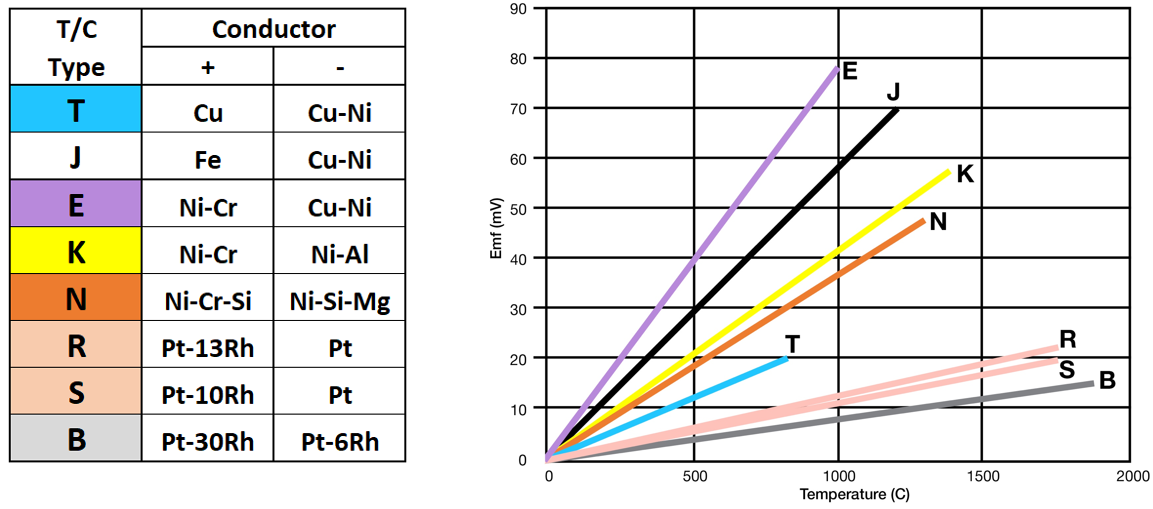

Known for their fast response and wide temperature range, thermocouples are suited to many industrial environments. Output voltages vary based on the metals used. For example, a Type K thermocouple uses Nickel-Chromium as the positive conductor and Nickel-Alumel as the negative conductor. (See figure 6.)

Figure 6: Thermocouple Type K

Different Thermocouple Types

Thermocouples come in various types, each designated by a letter and characterized by specific metal combinations, temperature ranges, sensitivities and suitable applications. The most common types are Type K, Type J, Type E and Type N. See Figure 7 for a breakdown of the most common thermocouple types.

Figure 7: Different Thermocouple Types.

Selecting the Right Temperature Sensor

Both RTDs and thermocouples are sensors used to measure temperature and the choice of which to use should be based on the application requirements. When choosing between an RTD and a thermocouple, consider the following factors:

- Temperature Range: Thermocouples cover a broader range, up to and over 2000 °C (3632 °F) making them suitable for extreme temperatures. RTD sensors are better suited to lower temperature ranges up to 600 °C (1112 °F).

- Accuracy: RTDs generally provide higher accuracy and stability over time.

- Response Time: Thermocouples typically have faster response times.

- Environment: Consider the presence of corrosive elements, vibration and electromagnetic interference.

- Cost: RTDs are usually more expensive than base metal thermocouples but may offer cost savings over time due to their stability and longevity.

Understanding the specific requirements of your application will guide you in selecting the most appropriate temperature sensor.

Ready to learn more?

Now that you better understand the difference between RTDs and thermocouples, their advantages and disadvantages and when it’s proper to use each, you can choose which one is best for your application. The conditions of your specific application are important to consider when deciding whether you need an RTD or thermocouple temperature sensor.

Here are some temperature sensor-related articles that you may find interesting:

- Product Review: New RTDs and Thermocouples

- Fitting a Thermowell to Bimetal Thermometers or RTDs/Thermocouples

- How Much Do Industrial Bimetal Thermometers Cost?

- How Much Do Temperature Sensors Cost?

Feel free to contact us and speak to a product specialist who can address any other questions you may have. In the meantime, download our guide to learn more about our product line.

Tino Goncalves, Product Sales Manager

Tino is the Product Sales Manager here at Ashcroft. He has over 20 years of experience in test and measurement instruments and holds a Bachelor of Science in management and electrical engineering.

Topics: