Subscribe now and get the latest blog posts delivered straight to your inbox.

What is a temperature sensor?

In a recent Understanding the Basics blog article, we reviewed how temperature is measured in industrial applications using different types of thermometers. In this article, we will focus on the temperature sensors used to measure temperature in original equipment manufacturing (OEM) systems, light industrial processes or even more complex applications.

No matter what the purpose, inaccurate temperature measurements can have serious consequences for your entire operation, so you'll want to be sure you use accurate and reliable instruments to do the job.

If you are new to OEM applications or simply need a refresher on the basics of temperature sensors, you've come to the right place. Here we will review different types of temperature sensors, how they work, and what to look for when selecting the best option for your specific needs. At the end of the article, you will find additional resources related to temperature measurement that may interest you.

What is a temperature sensor and where are they used?

Unlike thermometers that provide a visual-only reading of the process temperature, sensors use technology to detect temperature changes in the process and convert it to a readable output signal. The signal is sent to a control system that is visible to operators who monitor any changes that occur.

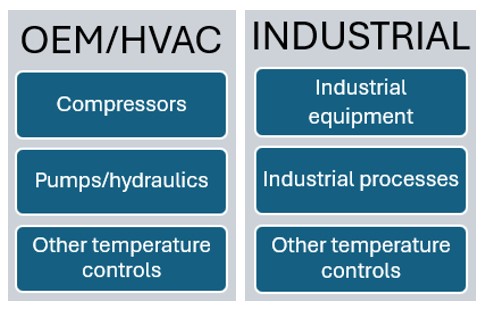

These devices can be used in a variety of applications, including:

Figure 1: Temperature Sensor Applications

Different types of temperature sensors to choose from

There are many kinds of temperature sensors, each serving a slightly different purpose. Each type has its advantages and limitations. Before you choose the one that is suitable for your application, you will need to consider accuracy requirements, temperature range, environmental conditions and more.

Some of the most common types of temperature sensors include:

Thermocouples

Thermocouples are known for their wide temperature ranges (over 2000 °C or 3632 °F) and fast response times.

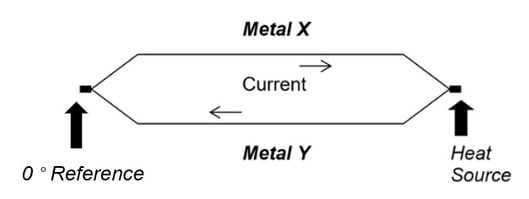

They are made from two different metals that are joined at one end. This is called a junction which is typically connected to a measuring device.

When there is a temperature difference between the joined end and the other ends, a voltage is generated that can be measured and converted into a temperature reading. The reference junction temperature in millivolts will increase or decrease with temperatures introduced to the thermocouple junction. The millivolt difference of the thermocouple output varies depending on the materials used.

Figure 2: Thermocouple junctions.

Thermocouples are typically more cost-effective, but less accurate, less stable and can drift over time. However, these sensors, including the Ashcroft® S80 Thermocouple Temperature Probe have a faster temperature response, are more rugged and can withstand harsher conditions, such as vibration and high temperatures.

Figure 3: Ashcroft® S80 Thermocouple Temperature Probe

Resistance Temperature Detectors (RTDs)

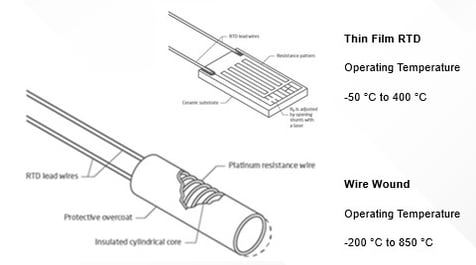

Resistance Temperature Detectors (RTDs) provide high accuracy and stability and are often used in industrial applications. These sensors' resistance values change with temperature. RTDs can either be a wound wire or a thin film construction. So, the resistance is relative to temperature, and resistance increases or decreases with temperature. Depending on your application, you can choose 2-wire, 3-wire and 4-wire RTD configurations.

Figure 4: Thin film and wire wound RTD.

RTDs like the Ashcroft® S81 RTD Temperature Probe are more accurate, stable and linear within a temperature range up to 600 °C (1112 °F). These sensors are typically used for lower temperature ranges and offer higher accuracy, stability and repeatability than other sensors.

Figure 5: Ashcroft® S81 RTD Temperature Probe

Thermistors

Similar to RTDs, thermistors (thermally sensitive resistors) change resistance with temperature. Thermistors have a higher resistance change per degree of temperature change than RTDs. This provides for a higher resolution.

They come in two types: Negative Temperature Compensation (NTC) or Positive Temperature Compensation(PTC). An NTC Thermistor’s resistance will decrease as temperature increases. They are commonly used in temperature control devices such as thermostats. A PTC Thermistor’s resistance will increase as temperature increases. They are commonly used for circuit protection.

Figure 6: NTC Thermistor

Integrated Circuit (IC) Temperature Sensors

An IC temperature sensor is a two-terminal transducer that produces an electronic output proportional to changes in temperature. Typical output is 10 mV per °C. They are known for their accuracy over a limited temperature range and are commonly used in electronic devices.

Figure 7: IC Temperature Sensor

Custom Configured OEM Temperature Sensors

In many applications, it may not be possible to use a simple temperature sensor with a thermocouple or resistive output. In these cases, it is better to have a custom-designed sensor solution like the Ashcroft® KTS1 Temperature Sensor.

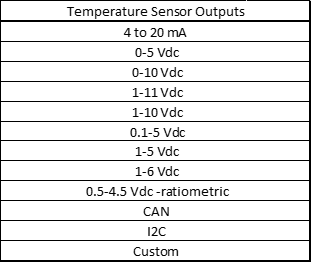

The base sensing element of the KTS1 is an RTD. The RTD is mounted in a probe with a threaded fitting for mounting and electronics to convert the RTD temperature measurement to an output (see table below) that can be easily used in the system. The process connection thread can be custom. The electrical connection can be a custom connector or a cable.

Figure 8: Ashcroft® KTS1 Temperature Sensor

Figure 9: Temperature Sensor Outputs

Go beyond the basics.

Now that you know a little more about temperature sensors and how they work, you may want to get some more in-depth information. Here are a few related articles for your reference.

- When to Use an RTD vs. a Thermocouple Temperature Sensor

- Product Review: New RTDs and Thermocouples

- How Much Do Temperature Sensors Cost?

- How Does a Thermocouple Work?

Feel free to reach out to our temperature specialists here at Ashcroft to answer all of your temperature measurement questions. In the meantime, feel free to download our guide.

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.

Topics: