By:

Dave Dlugos

Product Technical Leader

Published on:

January 18th, 2024

Subscribe now and get the latest blog posts delivered straight to your inbox.

What is a pressure transducer?

By:

Dave Dlugos

Product Technical Leader

Published on:

January 18th, 2024

A pressure transducer, which can also be referred to as a pressure transmitter or pressure sensor, is an electronic device that measures and monitors the air, gas or liquid pressure flowing through industrial systems. Although they appear small, these instruments are built with advanced technology to provide accurate and reliable pressure measurements at different stages of the process.

Ashcroft is an industry leader in pressure measurement instrumentation and created this article to provide a basic foundation of information about transducers for the industry novice.

Read on to learn how they work and where they are used. You will also get a high-level overview of the different types of sensors, manufacturing standards, sensor accuracy and more. When you are done reading, you will also find additional resources about transducers that may interest you.

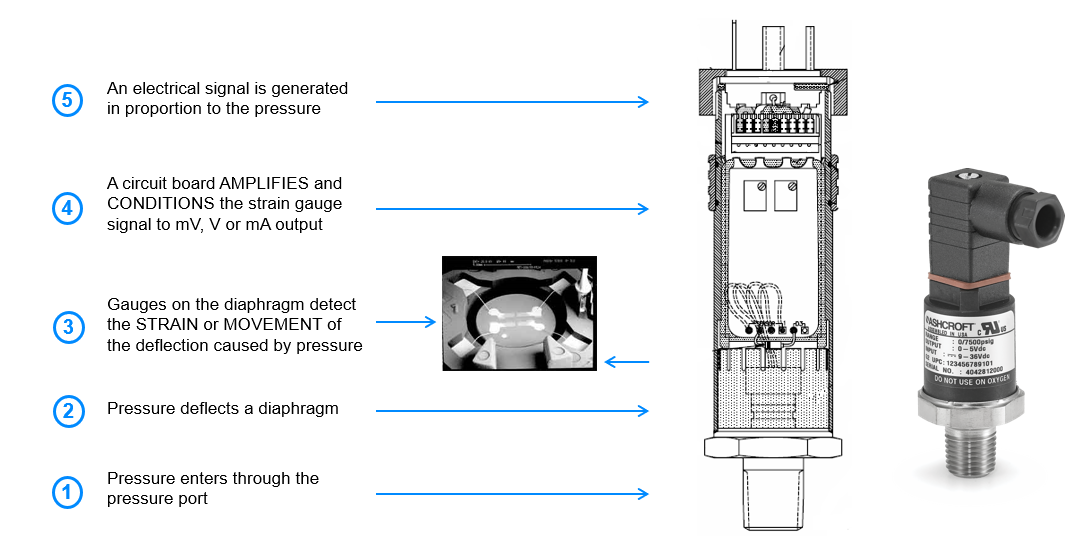

How does a pressure transducer work?

Pressure transducers convert pressure measurements to an output electrical signal (current or voltage). Common transducer outputs are 4 to 20 mA (milliamps), voltage ranges 0-5 Vdc (voltage direct current), 0-10 Vdc and millivolt per volt.

Figure 1: How a pressure transducer works.

Where are pressure transducers used?

Pressure sensors are engineered to withstand extreme conditions (intense cold or high heat), as well as significant shock and vibration. Transducers can be found in any application that requires continuous monitoring of the process. Common applications include:

- HVAC/R equipment

- Food and pharmaceutical plants

- Off-road transportation

- Hydraulics

- Pneumatics

- Semiconductor manufacturing

![]()

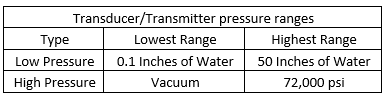

What is a transducer's pressure range?

These sensors can accurately measure pressure ranges starting from as low as 0-0.1 inches of water (low pressure) to 72,000 pounds per square inch (psi) for high pressure). Their precision levels range from ±0.02% to ±2.00% of span. The type of sensor you use (low pressure or high pressure) will depend on the application requirements.

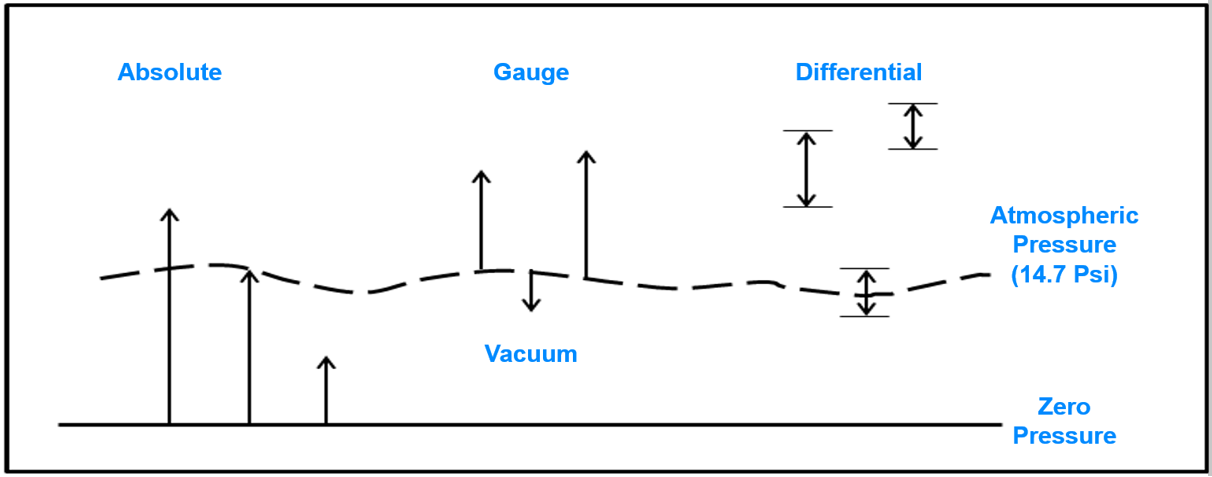

What types of pressure does a transducer measure?

Absolute pressure. Absolute pressure occurs when air is completely absent. Only then is a perfect or total vacuum created. There is no negative absolute pressure. When pressure is measured, it will be the same and will not fluctuate regardless of atmospheric or barometric pressure.

Gauge pressure. A positive pressure that is greater than atmospheric or barometric pressure using ambient pressure as the reference.

Vacuum pressure. A negative pressure that is less than atmospheric or barometric pressure using ambient pressure as the reference.

Differential pressure. A measurement of the difference in pressure between two points in a system.

How accurate are pressure transducers?

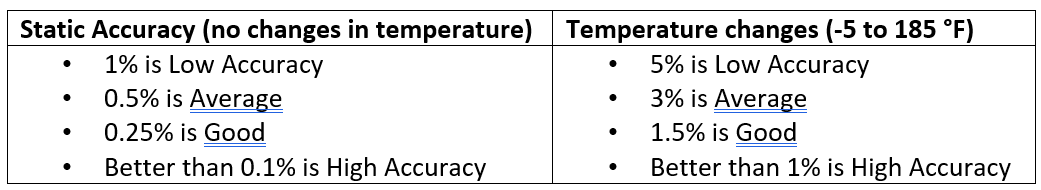

Depending on your process, the accuracy of the transducer can be crucial. For instance, if you are controlling an isolation room, it is critical to maintain certain pressure levels and have a highly accurate transducer. On the other hand, if you are measuring and monitoring a simple process like measuring water levels, you may only need the transducer to produce moderately accurate measurements or even low-accurate readings.

The accuracy of a transducer will also depend on whether you include temperature effects or not. The following table give you an idea of the accuracy ranges you will find in a transducer:

Of course, more elements contribute to an overall accuracy or sensor performance, all of which are included in the manufacturer’s accuracy statement. To learn more about how accuracy is defined and all the elements that are covered for transducers and transmitters, read our e-book, Accuracy Statement for Pressure Instruments.

Of course, more elements contribute to an overall accuracy or sensor performance, all of which are included in the manufacturer’s accuracy statement. To learn more about how accuracy is defined and all the elements that are covered for transducers and transmitters, read our e-book, Accuracy Statement for Pressure Instruments.

What technology is used in transducers?

Pressure sensors incorporate various sensing technologies, which can impact the accuracy of the instrument. Here are a few types of technology commonly found in pressure sensors

Chemical Vapor Deposition (CVD) Thin Film Sensor

CVD is one example of the advanced sensing technology used in high-accuracy pressure instruments. It is designed to maintain high reliability and performance across all mid- to high-pressure applications. Ashcroft transducers, including the S1 OEM Pressure Sensor and the Ashcroft G2 Pressure Transducer, as well as the high-purity ZT and ZX Pressure Transmitters, all use CVD sensing technology to achieve precise and consistent pressure measuring. Watch this video to learn about CVD technology.

Si-GlasTM Silicon Capacitive MEMS

Si-GlassTM is another example of state-of-the-art technology that is designed for precise, consistent pressure measuring for exceptionally low-pressure applications. For example, this technology is for air-flow measurements, aspiration, room pressurization control and leak detection. The Ashcroft CXLdp Pressure Transducer, the DXLdp Pressure Transducer and the Ashcroft ATE-2 Handheld Calibrator all use Si-Glas technology for their high accuracy, repeatability and stability. Watch this video to learn more about Si-GlasTM technology.

Go beyond the basics.

Now that you have a basic understanding of pressure transducers and how these sensors work in different applications, you may be ready to dig in a little deeper. Here are a few related articles that can get you started.

• Choosing the Right Pressure Sensor: 5 Factors to Consider

• Choosing a Pressure Transducer for Critical Environments

• How much do pressure transducers cost?

In the meantime, feel free to contact us today to talk to one of our industry experts with questions or download our e-book to learn more.

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.