By:

Dave Dlugos

Product Technical Leader

Published on:

January 15th, 2025

Subscribe now and get the latest blog posts delivered straight to your inbox.

What is a Thermocouple

By:

Dave Dlugos

Product Technical Leader

Published on:

January 15th, 2025

A thermocouple is a type of electrical temperature sensor that is used to measure and monitor temperature changes in process applications. Similar to resistance temperature detectors (RTDs), these sensors are designed to ensure accurate temperature readings in applications where precise temperature control is essential for safety and efficiency.

As part of Ashcroft's Understanding the Basics series, this article will provide you with a high-level review of these instruments, including their origin, how they work for different applications and more. You will also gain insights about when to use (or not to use) this type of sensor and be directed to additional resources that can help you deepen your knowledge on the topic of temperature sensors.

This information comes from 40 years of industry experience with temperature and pressure measurement, design, engineering, and product management, which includes 17 years working with Ashcroft - a leader in temperature and pressure instrumentation.

What is the origin of the thermocouple?

The origin of a thermocouple dates back to 1821 when Thomas Johann Seebeck discovered that a low electric current is generated when two conductors of different metals are linked together and subjected to a temperature difference. The two conductors that are connected are known as a thermocouple.

Figure 1. Example of Seaback effect.

How a thermocouple works.

A thermocouple is composed of two kinds of metal wires joined at one end to form a junction, known as the hot junction where temperature is measured. The other ends of the wires are connected to a reference point, referred to as the cold junction. The cold junction is normally referenced to 0 degrees C. When there is a temperature difference between the hot and cold junctions, a voltage is generated, which can be measured and correlated to temperature.

In the example below, we have a welded thermocouple junction that is heated to 100 °C (the hot junction). If we lower the temperature at the other end of the thermocouple wires to 0 °C (the cold junction), we have a temperature difference of 100 °C, which for this K-type thermocouple will produce a 4.096 millivolt signal.

Figure 2. Thermocouple working example.

Thermocouple probes.

Ashcroft manufactures two types of thermocouple probes which are made to ASTM standards. Their sheath materials are made with 316 stainless steel or Inconel 600, providing a high insulation resistance (IR) of 1,000 megaohmes (MΩ) at 500 volts.

- Direct-mount thermocouples like the Ashcroft® S50 have the sensor positioned at the tip of the probe. They use minerally insulated (MI) cables and have a customer-specified lag; the most common (shown below) is the nipple union nipple lag. The electrical junction box, or head, is directly mounted on the probe.

- Remote-mount thermocouples, like the Ashcroft® S80 and S81, also have the sensor at the tip of the probe and use MI cables. They have a transition piece to connect the MI cables to the extension wire cable. The extension wire cable (which has to be the same as the thermocouple type) can come in a variety of wire insulation types and can have flex armor for additional protection.

Figure 3. RTD construction example with a nipple union nipple lag.

Thermocouple junctions.

There are two types of thermocouple junctions:

- Grounded junctions have the junction welded to the probe tip.

- Ungrounded junctions have the junction isolated from the probe tip.

Figure 4. Grounded thermocouple junction.

Figure 5. Ungrounded thermocouple junction.

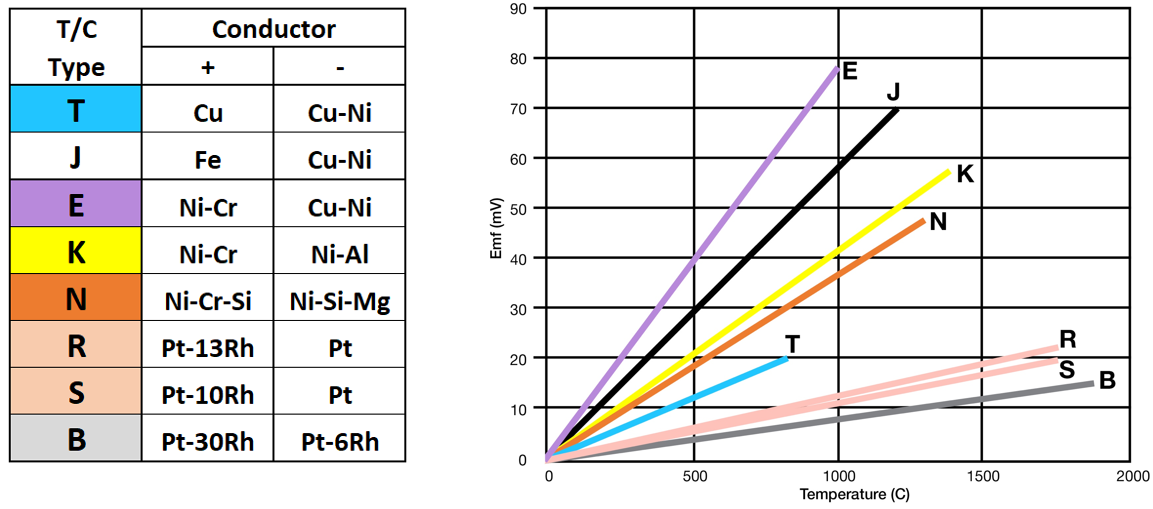

8 thermocouple types.

You can choose one of eight types of thermocouples, depending on your application:

- Type T is typically used for cryogenic and freezer applications.

- Type J is used in many general industrial applications.

- Type E is used for higher accuracy measurement.

- Type K is the most commonly used thermocouple for general industrial applications.

- Type N is used in applications that need better oxidation resistance and less drift.

- Type S is used for high-temperature furnaces. '

- Type R is used for high-temperature heat treatment and biotech applications.

- Type E is the highest-temperature thermocouple. Thermocouple types vary in the usable temperature range and cost.

Thermocouples used for higher temperature ranges, including the S, R and E are more expensive than other types.

Figure 6. Thermocouple types with a combination of select alloys.

Ready to go beyond the basics of thermocouple temperature sensors?

Now that you have a basic foundation of Thermocouples and how they work, you likely have more questions. Here are a few helpful resources for your reference:

- How Does a Thermocouple Work?

- Which Thermocouple Lead Wire is Best for My Application?

- Grounded vs. Ungrounded Thermocouple Junctions: Why Select One Over the Other?

- What is Thermocouple Calibration?

- How Much Do Temperature Sensors Cost?

- What is an RTD?

At any time, feel free to contact one of our product experts with any questions you have. In the meantime, download our guide to learn about our line of custom RTD and Thermocouple probes.

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.