Subscribe now and get the latest blog posts delivered straight to your inbox.

Which Thermocouple lead wire is best for my application?

Not every application is the same, so you need to get the right equipment for your specific needs. When it comes to temperature measurement, inaccurate readings can severely impact your process. So, how can you ensure you are correctly and reliably monitoring temperature?

Whether your application is for light-industrial temperature measurements or critical heavy-duty installations, Ashcroft®, an industry leader in pressure and temperature instrumentation, has developed a line of reliable thermocouple probes that are custom-configured to meet your specific application requirements.

This article will discuss how to choose the best thermocouple lead wire for common applications. When you are done reading, you will also find additional related resources that can help you gain more insight into thermocouples.

What you need to know about thermocouples.

Thermocouples are known for their wide temperature ranges (over 2000 °C or 3632 °F) and fast response times.

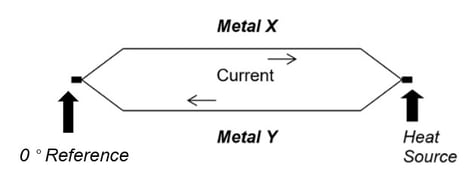

They are made from two different metals that are joined at one end. This is called a junction which is typically connected to a measuring device.

When there is a temperature difference between the joined end and the other ends, a voltage is generated that can be measured and converted into a temperature reading. The reference junction temperature in millivolts will increase or decrease with temperatures introduced to the thermocouple junction. The millivolt difference of the thermocouple output varies depending on the materials used.

Figure 1: Thermocouple junctions.

The Ashcroft® S80 Thermocouple Temperature Probe is a remote-mount style probe. Consisting of an MGO cable sensor with a transition to lead wire. The type of lead wire you choose depends on your application.

Figure 2: Ashcroft® S80 Thermocouple Temperature Probe

What is a thermocouple lead wire?

A thermocouple lead wire is the wire that connects the thermocouple probe to the temperature transmitter or control system.

It must be the same type of wire as the thermocouple used. For example, a K-type probe must use K-type extension wire, otherwise, another junction will be created, and it will not give the proper temperature reading.

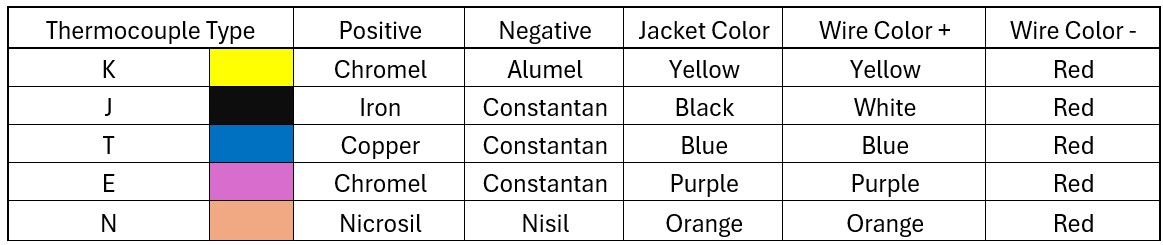

Thermocouple lead wires are color-coded according to ASTM MC96.1 to show the type of thermocouple it is.

Figure 3: ASTM MC96.1 Thermocouple Lead Wire Color Coding.

What type of lead wire do you need?

The type of lead wire you will need is determined by the application. Answering the following questions will help you narrow down your options.

1. Is the thermocouple a single or a dual design?

- A single design will require a two-wire cable

- A dual design will require a four-wire cable

2. What size wire gauge is needed and is it solid or stranded wire?

A thermocouple lead wire can be either solid wire or stranded wire.

- Solid wire is not as flexible as stranded wire, so it is much more common to use stranded lead wire.

- The stranded wire makes the installation of the wire easier for the end user to install.

The wire gauge size depends on two things:

- The length of the wire

- Whether the wire is a single or a dual

Care must be taken when running long lengths of thermocouple lead wire, the wire gauge size must be large enough not to distort the very low signal the thermocouple produces. It is best practice to keep the lead wire as short as possible.

Running lengths of wire over 100 feet is not recommended. The limiting factor on wire size is also the cable outer diameter must fit inside the transition piece. So, it is common to see 24 AWG wire used in dual applications and 20 AWG wire used in single applications.

3. What type of cable jacket insulation should be used?

The type of insulation used is very important. The ambient temperature of the environment around the cable is a limiting factor.

- For normal room temperatures, a PVC jacketed cable can be used.

- For high ambient temperatures, you can use PFA jacketed cable. Fiberglass jacketed cable is also good for higher temperatures and harsh environments but it is difficult to work with so it should only be used when needed.

- When flexibility is a concern, a Silicon jacketed cable is pliable enough to be used in these instances.

4. Do you need a shield cable?

If the environment around the lead wire has electrical interference present, it is good practice to use a shielded cable to protect the very low signal from the thermocouple.

5. Does the lead wire need additional protection from abrasions and impacts?

If the answer is yes, it is common practice to install the cable in Flex Armor. The Flex Armor will provide very good protection in harsh environments.

Ready to learn more?

Now that you know a little more about temperature sensors and which lead wires are used in different applications, you may want to get some more in-depth information. Here are a few related articles for your reference.

• When to Use an RTD vs. a Thermocouple Temperature Sensor

• Product Review: New RTDs and Thermocouples

• How Much Do Temperature Sensors Cost?

• How Does a Thermocouple Work?

Feel free to reach out to our temperature specialists here at Ashcroft to answer all of your temperature measurement questions. In the meantime, feel free to download our guide.

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.

Topics: