By:

Tino Goncalves

Product Sales Manager

Published on:

April 17th, 2023

Last updated on:

December 11th, 2025

Topics:

Subscribe now and get the latest blog posts delivered straight to your inbox.

How Does an RTD Work?

By:

Tino Goncalves

Product Sales Manager

Published on:

April 17th, 2023

Last updated on:

December 11th, 2025

Topics:

Resistance temperature detectors (RTDs) are passive components whose resistance changes with a change in temperature. This can be measured very accurately, enabling an RTD to translate temperature into a stable electrical signal, even in demanding industrial environments.

As a trusted resource in pressure and temperature measurement, Ashcroft helps users understand how RTDs function so they can select the right sensing technology for their process.

In this article, you’ll learn how an RTD senses temperature, how the materials and construction of the sensing element influence accuracy, why wiring configuration matters and how these factors help determine which RTD design is best suited for your application.

What is an RTD's electrical resistance?

Electrical resistance is the opposition to the flow of the electrical current. RTD temperature sensors rely on the relationship of resistance to temperature. For example, as the temperature rises, the resistance of the RTD element increases; and as the temperature decreases, the resistance decreases.

The reliability of this resistance response is influenced by two key factors: the metals used in the sensing element and the way the RTD is built and wired into the circuit. The sensing element material determines how stable, repeatable and accurate the resistance change will be.

Materials that help maintain accuracy

Material choice directly influences how well the RTD maintains accuracy across different operating conditions.

1.Platinum 100 ohm

Pt100 RTD sensors are passive components and require an excitation current to produce an output signal. This is the preferred RTD element material because it offers:

- Excellent corrosion resistance

- Proven long-term stability

- A wide range of temperature, from -200 to +850 °C.

These characteristics make platinum suitable for processes requiring accuracy over time, including cryogenic systems where temperatures can reach –196 °C.

2. Nickel and Copper.

These materials are less common than platinum options and have limited temperature ranges.

- Nickel offers good corrosion resistance, but ages more quickly and loses accuracy at higher temperatures. This material is usable in applications with temperature ranges from –80 to +260 °C.

- Copper offers the best resistance to temperature linearity of the three RTD types. However, it oxidizes at higher temperature. It is usable in applications with temperature ranges from –200 to +260 °C.

How does RTD element construction impact on performance?

Instrument accuracy, linearity and usable temperature range are all affected by whether the RTDs sensing element is a wire-round or thin film construction. Each is rated based on its resistance at 0°C.

Wire-Wound RTDs

This type of RTD is ideal for applications requiring precision under extreme temperature conditions. They are made from a fine platinum wire coil that provides excellent accuracy and long-term stability, and supports the broadest operating range from –200 to +850 °C.

Thin-Film RTDs

Thin-film RTDs are often selected for less extreme temperature ranges. They use a platinum layer deposited on a ceramic substrate, are compact and fast to respond. These RTDs typical have an operating range of –50 to +400 °C.

Figure 1: Wire round vs. thin film construction

What are the effects of lead wire and wiring configurations?

Because an RTD measures resistance, any resistance introduced by lead wires influences accuracy. Wiring configuration therefore is essential to how accurately the RTD performs once installed.

Typical lead-wire options on for an RTD:

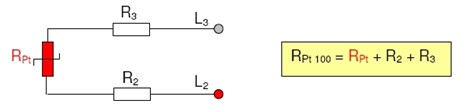

2-wire RTD

The 2-wire RTD configuration is the simplest among RTD circuit designs. A single lead wire connects each end of the RTD element to the monitoring device. The total circuit resistance includes the lead wire resistance. This is the least accurate of the configurations and used for applications with short lead lengths.

Figure 2: 2-Wire RTD

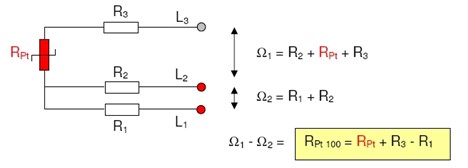

3-wire RTD

The 3-wire RTD configuration is the most common RTD circuit design used in industrial processes. In this setup, two lead wires are connected to one side of the sensing element and a single lead wire is connected to the other side. By allowing the monitoring device to compare the resistance of the paired leads, this configuration effectively compensates for the lead wire resistance on one side of the element, significantly improving overall measurement accuracy.

Figure 3: 3-Wire RTD

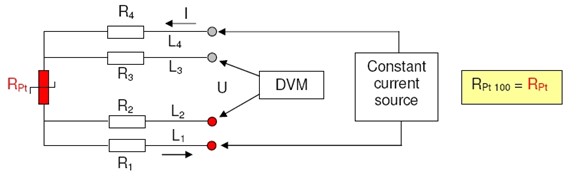

4-wire RTD

The 4-wire RTD configuration is the most complex and typically the most expensive, but it provides the highest level of measurement accuracy. In this design, two pairs of lead wires connect to the sensing element, allowing the monitoring device to fully cancel out the lead wire resistance on both sides of the circuit.

Figure 4: 4-Wire RTD

Why do accuracy classes matter?

Accuracy classes identify how closely an RTD element matches the ideal resistance-temperature curve defined by IEC 60751. Common accuracy classes include:

- Class B: ±0.3 °C (widest operating range)

- Class A: ±0.15 °C

- Class AA: ±0.1 °C (tightest tolerance)

Where RTDs are commonly used?

RTDs are widely used in industries that rely on accurate, stable temperature measurements, including:

- Oil and gas industries

- Power plants

- Chemical and refining processes

- Pharmaceutical and biotechnology systems

- Cryogenic storage and low-temperature production

- Compressor and turbine monitoring

- Safety shutdown systems and critical control loops

Ready to learn more?

Now that you understand how an RTD works and how materials, construction and wiring influence accuracy, you can better evaluate which configuration supports your application.

If you have more questions, contact us to speak to a temperature specialist. In the meantime, review our additional resources below or download our guide to learn about custom RTDs and Thermocouples offered at Ashcroft.

Tino Goncalves, Product Sales Manager

Tino is the Product Sales Manager here at Ashcroft. He has over 20 years of experience in test and measurement instruments and holds a Bachelor of Science in management and electrical engineering.