By:

Dave Dlugos

Product Technical Leader

Published on:

October 27th, 2025

Subscribe now and get the latest blog posts delivered straight to your inbox.

Ways to Calibrate a Pressure Transducer

By:

Dave Dlugos

Product Technical Leader

Published on:

October 27th, 2025

Across industries like manufacturing, energy, HVAC, and process control, accurate pressure measurement is critical to maintaining safety, efficiency, and product quality. Over time, even high-quality pressure transducers can experience drift — a gradual deviation between actual and measured pressure caused by vibration, temperature changes, or normal wear.

Calibration restores accuracy by comparing the transducer’s output to a known reference standard and adjusting as needed. But with multiple calibration methods available, the right approach depends on your environment, equipment and accuracy requirements.

As a recognized leader in pressure and temperature instrumentation, Ashcroft addresses this challenge with customers frequently. In this article, you’ll learn why pressure transducer calibration is essential, how zero and span adjustability preserve accuracy over time, the difference between primary and secondary calibration standards, and the lab and field methods that are best suited for both every day and hazardous applications.

Why calibrate a transducer?

Pressure transducers convert applied pressure into an electrical output signal. Over time, those signals can drift away from the true pressure reading due to mechanical stress or environmental factors.

Calibration verifies that the transducer’s output aligns with a known primary or secondary reference standard. If deviations are found, adjustments can be made to bring it back into specification.

According to the American Society of Mechanical Engineers (ASME), the reference instrument used for calibration should be at least four times more accurate than the device being tested. This guideline is often called the 4:1 rule. For example, a transducer rated at ±1% of full-scale accuracy should be calibrated using a standard accurate to ±0.25% or better.

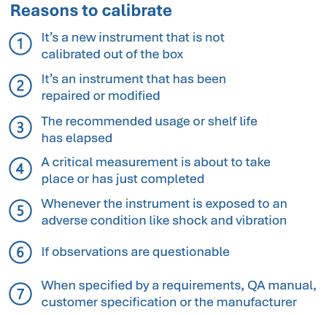

Figure 1. Reasons why pressure calibrations may be needed

What is zero and span adjustability in the calibration process?

A key part of any calibration process is knowing what’s actually being adjusted — the zero and span points that define accuracy.

Every pressure transducer has two critical reference points — zero and span:

- Zero offset is the output error at the low-pressure end of the range (or full vacuum for compound ranges)

- Span offset is the output error at the full-pressure end of the range

Over time, repeated pressure cycles, temperature changes, or component aging can cause drift at these endpoints. Zero and span adjustability allows users to correct those shifts, aligning the transducer’s output signal with the true pressure values without sending the unit back to the manufacturer.

Benefits of zero and span adjustability

- Field serviceability: Enables recalibration on-site, minimizing downtime

- Cost efficiency: Reduces the need for external recalibration service or sensor replacement

- Accuracy retention: Maintains reliable performance in demanding applications

However, while zero and span adjustments correct performance at the low and high ends of the range, but not necessarily in between them.

Now that we’ve defined what calibration adjusts, let’s look at how it can be done. Calibration methods generally fall into two categories — laboratory calibration for high accuracy and traceability and field calibration for quick verification and adjustment.

Primary and secondary calibration standards

Every calibration process relies on reference standards that define accuracy. These are classified as primary or secondary:

- Primary standards are the highest accuracy reference devices available. They establish pressure based on fundamental physical principles rather than a comparison. A deadweight tester is the best-known example of a primary pressure standard. Because it generates a known, traceable pressure, it’s used in laboratories to validate other instruments.

- Secondary standards are instruments that have been calibrated against a primary standard. They maintain high accuracy and are used to calibrate working instruments in both laboratory and field settings. Examples include digital test gauges and handheld calibrators.

Understanding how primary and secondary standards relate ensures your calibration process maintains a clear traceability path back to a national standard such as the National Institute of Standards and Technology (NIST), guaranteeing accuracy and compliance in your measurement records.

While calibration standards define the reference for accuracy, the calibration method describes how that reference is applied in practice. The following sections describe these methods in detail — from laboratory precision testing to field and hazardous-area calibration.

In the lab: manual calibration with a deadweight tester

Deadweight testers, like the Aschroft® Deadweight Tester 1305D, is considered the primary standard for pressure calibration and the best approach for high-precision verification. It operates on the fundamental principle that pressure is created by applying a known force over a specific area.

How it’s done:

- Connect the transducer and a reference gauge to the tester

- Apply known weights to generate pressure points across the measurement range

- Compare the transducer’s electrical output (voltage or current) with the reference readings

- Adjust zero and span until both match

This method delivers extremely high accuracy and traceability but requires controlled conditions, making it best suited for laboratory environments or when calibrating master reference instruments.

In the field: method using handheld or digital calibrators

When sending instruments to a lab isn’t practical, technicians can use portable instruments like the Ashcroft® ATE-2 Handheld Calibrator and Ashcroft's Digital Test Gauges to provide a versatile solution in the field for preventive maintenance, quick checks and on-site verification.

How it’s done:

- Connect the transducer and calibrator in a loop with a pressure source

- Apply pressure using a pump or regulator

- Compare the transducer output with the calibrator’s display

- Adjust zero and span either mechanically or through configuration software if the readings differ

This approach allows for regular field verification with good accuracy and minimal downtime — ideal for maintaining performance between lab calibrations.

Calibrating pressure transducers in hazardous areas

In industries such as oil and gas, chemical processing, or paint and coating, calibration often occurs in hazardous environments where explosive gases, vapors, or dusts are present. In these cases, transducers must be certified as explosion-proof (XP), intrinsically safe (IS), or non-incendive (NI) — each offering protection in a different way:

- Explosion-proof (XP): Contains any ignition within the housing

- Intrinsically safe (IS): Limits electrical energy to prevent sparks

- Non-incendive (NI): Restricts energy under normal conditions

Traditional calibration methods that involve opening the housing or adjusting internal screws can’t be performed safely in these environments. To address this, the Ashcroft® E2S Intrinsically Safe Pressure Transducer and E2F Explosion Proof Pressure Transducers incorporate zero and span adjustability designed for hazardous areas.

Magnetic calibration with Ashcroft® pressure transducers

The Ashcroft® E2 Pressure Transducer Series features an external magnetic calibration system that allows users to perform precise zero and span adjustments without opening the housing. These options offer safe, efficient and repeatable field calibration in hazardous or outdoor applications.

How it works:

- The E2G includes an internal magnetic sensor that responds to a calibration magnet tool

- Holding the magnet near marked points on the housing engages calibration mode

- This allows zero and span corrections to be done quickly and safely - Watch video for details

Magnetic advantages

- Non-invasive: Preserves explosion-proof integrity and IP66/67 seal

- Fast: Calibration can be completed in minutes

- Safe: No tools or electrical exposure in hazardous areas

- Repeatable: Ensures long-term stability and SIL 3 safety compliance

When calibrating in hazardous zones be sure to only use approved magnetic tools and ensure all portable calibrators or power supplies are rated for the same hazardous area or isolated by barriers. To maintain certification compliance, always follow the manufacturer’s installation and safety documentation.

Regardless of the application, regular calibration ensures pressure transducers deliver consistent, reliable measurements throughout their service life. Understanding zero and span adjustability, along with the role of primary and secondary standards, helps determine the best method for maintaining accuracy.

Ready to learn more?

This information offers a solid foundation for calibrating your pressure instrument, but you may have more questions. Here are a few additional articles that may be of interest.

- Benefits of Zero and Span Adjustability

- What Causes Zero and Span Offset in Pressure Sensors

- Calibrating Low-Pressure Sensors in Critical Environments

- Choosing Pressure Transducers for Hydrogen and Hazardous Locations

- How Much Do Pressure Transducers Cost?

Contact us if you want to speak to a product expert to get your questions answered.

Dave Dlugos, Product Technical Leader

Dave Dlugos has a BSEE degree and 40 years of experience in the measurement industry performing design engineering and product management. He has earned 4 U.S. patents and joined Ashcroft in 2007, currently as the Product Technical Leader. He is a senior member of the International Society of Automation (ISA), past ISA District 1, Vice President, past ISA water and wastewater division board member and the past President of CT Valley ISA Section.