Published on:

April 14th, 2025

Subscribe now and get the latest blog posts delivered straight to your inbox.

What Causes Offset in the Output of a Transducer at Zero and Span?

Published on:

April 14th, 2025

If you are using a transducer (also known as a sensor) to measure liquid, gas or air pressure in a critical environment, OEM application or high-purity manufacturing process, you need to have confidence in the accuracy of your instrument. That confidence will be tested if there is an offset in the output of that instrument at zero and span. However, if you understand the reason an offset can occur and what you can do to address it, your confidence will be restored.

Ashcroft, an industry leader in pressure measurement instruments, has consistently demonstrated reliability and excellence in the field of pressure measurement instrumentation. That's why we are often asked to share our expertise and shed light on topics like this one.

Read this article to learn how transducers measure pressure, possible causes of offset in the measurements and what you can do to ensure your instrument is providing you with the accuracy requirements for your specific application. You will also have the opportunity to deepen your knowledge through additional articles and resources available to you.

When you are done reading, you will know just what to do to prevent the offset from occurring or to fix the issue should it occur.

What you need to know about pressure transducers

In a separate article, we explained that pressure transducers are used to measure different types of pressure in a given application and convert the measurement to an output electrical signal (current or voltage). These pressure sensors can accurately measure pressure ranges starting from as low as 0-0.1 inches of water (low pressure) to 72,000 pounds per square inch (psi) for high pressure. Their precision levels range from ±0.02% to ±2.00% of span.

Whether you use a low-pressure or high-pressure sensor will depend on the application requirements.

Figure 1: Pressure transducer pressure ranges

What are zero and span offsets?

Zero and span offsets mean a pressure instrument will indicate a pressure reading, even when no pressure is applied. When this happens, potential errors affect the accuracy and reliability of the transducer's measurements, signaling the need to calibrate your instrument.

The greater the offset, the more significant the inaccuracy of the pressure measurement. Conversely, the better accuracy at zero and span, the more accurate your transducer will be in your application.

Note: when we talk about accuracy, we mean over a full span because if it is a compound unit zero is not zero. For compound measurements, you have to add 15 psi from the negative side into the span.

Here's how they are each classified:

- Zero offset refers to the output error at the bottom end of the measurement range. Although many people associate zero offset as 0 PSI, in compound ranges, it may represent full vacuum (-14.7 PSI) in compound ranges.

- Span offset indicates the output error at the full measurement range. For example, a zero to 30 psi unit has a span of 30 psi, but a vacuum to 30 psi has a span of 45 psi. A VAC TO 30 PSI has a span of 45 psi.

Zero offset and span setting errors are generally expressed as a percentage of span or a percentage of output.

Figure 2: Zero offset and span setting errors

Common causes of zero and span offsets

When determining to source of zero and span offsets, there are many factors to consider:

Manufacturing tolerances: There could be Inherent imperfections in the sensing elements or electronics of your instrument. This can cause slight inaccuracies at zero pressure. For instance, there may be limitations in the manufacturing process that prevent the ability to eliminate minor deviations during the production of the instrument's components. Over time, small discrepancies can accumulate and cause a noticeable offset in the pressure measurements.

Environmental factors: Changes in temperature and humidity can impact a pressure sensor's performance, which can lead to shifts in the output at zero and span. These environmental changes can cause the materials within the sensor to expand or contract, altering the sensor's baseline readings and affecting its overall accuracy.

Electrical noise: Unwanted fluctuations or spikes in electrical signals, radio frequencies, power lines or even lightning, for example, can also impact the performance of your pressure transducers. Whether or not your transducer can limit exposure to electrical noise can depend on the electronic circuitry it offers. The Ashcroft E2 and G2 for example, include electromagnetic interference/radio frequency interference (EMI RFI) protection capabilities that can block unwanted electromagnetic signals from interfering with their operation.

Drift: Pressure transducers can experience a gradual change in their output signal. This phenomenon, known as drift, can be caused by many factors, including mechanical stress. For instance, as the sensor components undergo repeated cycles of pressure, the materials, such as the metal diaphragm, may begin to wear down or deform slightly, leading to a shift in the baseline measurement.

Four ways to address zero and span offset issues

1. Choose a high-precision, fully-calibrated pressure sensor

Some transducers come pre-calibrated within their stated accuracy tolerances and are ready for immediate use. For example, sensors like the Ashcroft® E2G, Ashcroft® CXLdp and Ashcroft® DXLdp pressure transducers undergo extensive temperature compensation and rigorous calibration processes, to minimize zero and span offsets. These models offer plug-and-play convenience, ensuring accurate readings without additional calibration.

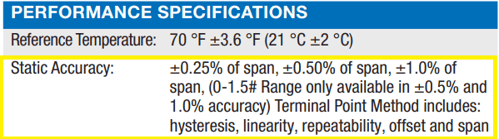

Performance specifications can be found on the manufacturer's product datasheet. For example, the Ashcroft® E2 datasheet shows that you can order these pre-calibrated out-of-the-box units in one of three accuracy options: ±0.25% of span, ±0.5% of span or ±1.0% of span.

Figure 3: Ashcroft® E2G Pressure Transducer datasheet accuracy specifications

2. Use transducers with zero and span adjustments

Zero and span adjustability help keep the pressure sensor’s accuracy within the tolerance of the stated accuracy. Some transducers feature zero and span potentiometers that allow users to fine-tune performance for specific applications. The Ashcroft® E2G, CXLdp, and DXLdp transducers all offer these adjustment options. The E2G model uniquely provides magnetic adjustments, enhancing usability.

3. Select a pre-calibrated sensor with no adjustment capabilities

There are also transducers that come pre-calibrated within their stated accuracy tolerances and are ready for immediate use. However, they lack user-adjustable zero and span controls. Products like the Ashcroft® G2 Pressure Transducer fall into this category. It offers a simple, lower-cost solution, but limited adjustability.

Note: Other factors contribute to the overall accuracy of your pressure instruments. These are all included in the manufacturer’s accuracy statement. To learn more about how accuracy is defined and all the elements that are covered for transducers and transmitters, download our guide.

Different methods of calculating accuracy

Manufacturers of pressure sensors are required to provide an accuracy statement that explains the method used to determine the accuracy of their instrument. Ideally, an accuracy statement should include a summation of all the error sources including nonlinearity, hysteresis, non-repeatability, zero offset and span setting - all of which contribute to how well the instrument performs. However, not all accuracy methods consider all of these errors.

Many manufacturers use the root of the sum squared (RSS) method, or the best fit straight line (BFSL) method to express instrument accuracy. These methods typically use statistically derived accuracy specifications that seem more accurate than the actual performance you experience once the instrument is installed.

Ashcroft uses the terminal point method. This approach includes both the zero and span offsets as part of the accuracy statement and determines the actual error for the instrument. We call this our TruAccuracy™ standard as it incorporates linearity, hysteresis, repeatability, and zero and span offsets, allowing for plug-and-play functionality in most applications.

Why accurate zero and span calibration matters

Correcting zero offset and span setting errors will affect the overall accuracy of the transducer. Changes made to the zero offset will cause a linear shift of the trend line, while changes to the span will affect the slope of the line. If zero and span setting errors are corrected, the accuracy of the transducer should be reevaluated. The bottom line is accurate calibration ensures that transducers provide precise readings across their entire operating range. The better the accuracy at both zero and span, the more reliable the transducer will be in its application.

Ready to learn more?

Now that you understand how zero and span offsets can occur and what you can do to address the issue, you are in a better position to make an informed decision about choosing the best pressure sensor for your needs. Of course, the right choice will depend on the application’s accuracy requirements and the operational conditions of your application. By making informed selections, you can ensure consistent performance and be more confident in your decisions.

- What are the Benefits of Zero and Span Adjustability?

- What are the Advantages of Ashcroft Pressure Transducers?

- Choosing a Pressure Transducer for Critical Environments

- Choosing the Right Pressure Sensor: 5 Factors to Consider

- How Much Do Pressure Transducers Cost? (6 Factors Impacting Price)

For personalized assistance, feel free to reach out directly to one of our experts.

In the meantime, download our guide, How Accurate is Your Accuracy Statement for Pressure Instruments?

Austin Haynie - OEM Territory Manager - Southeast

Austin joined Ashcroft in 2013 as an OEM Territory Manager covering the southeast region of the U.S. He has more than 16 years experience in the Pressure and Temperature Instrumentation business. Austin has a Bachelor's degree in Business Administration with a Minor in Business Management. He also earned an Associates Degree in Construction Technology.