By:

Darren Lewandowski

Territory Sales Manager

Published on:

October 21st, 2024

Subscribe now and get the latest blog posts delivered straight to your inbox.

Alternatives to Liquid-Filled Pressure Gauges for Vibration Protection

By:

Darren Lewandowski

Territory Sales Manager

Published on:

October 21st, 2024

This article was originally published on March 7, 2022, by John Girard and was updated on October 21, 2024.

Regardless of the industry, if your system requires a pressure gauge to measure and monitor process pressure, you want to ensure it offers the accuracy, safety and quality features you need. That includes protection from excessive pulsation and/or vibration found in challenging conditions. While there are many types of pressure gauges to choose from, the challenge is finding the one that works best for your specific situation.

Liquid-filled pressure gauges, direct drive pressure gauges and dampened movement options like Ashcroft’s PLUS!™ Performance all have pros and cons to consider. As a leading authority in pressure gauges, Ashcroft helps customers like you understand the advantages and drawbacks of different products so you can make a more informed purchasing decision.

Read this article to learn about the types of pressure gauges available for applications with high vibration, pulsation and other demanding conditions. When you are done you will be able to decide which one is best for your application. You will also find additional resources that can answer other common pressure gauge questions.

What is a Liquid-Filled Pressure Gauge?

A liquid-filled pressure gauge is a pressure measurement instrument that’s filled with a liquid like silicone or glycerin. This liquid serves as a cushion to stabilize the gauge needle, making it easier to read in conditions where pulsation and vibration are present. The liquid also reduces the impact of sudden pressure spikes that can lead to inaccurate readings or damage to the gauge itself.

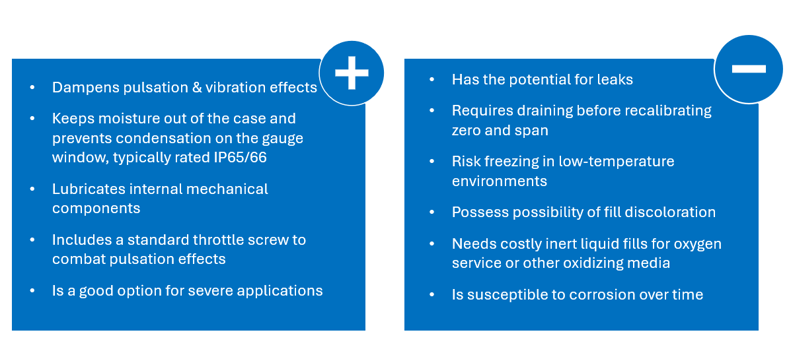

Liquid-Filled Pressure Gauge Pros and Cons

What is a Pressure Gauge with Dampened Movement Technology?

These dry-case pressure gauges use technology to dampen pulsation and vibration and improve gauge readability without the inconveniences of a liquid-filled gauge.

For example, numerous Ashcroft Pressure Gauges are available with PLUS!™ Performance technology. This proprietary Engineered Dampening Media (EDM) is injected into a canister that surrounds the gauge pinion shaft, movement plate, and backplate. A thixotropic liquid is used to adhere to the pinion to help reduce flutter, stabilize the pointer and enhance readability.

As gauge pressure increases or decreases, movement of the gauge pinion creates a shear load, which causes EDM molecules to scatter. The EDM material gets thinner at the layer being sheared. With applications involving vibration, this allows for the dampening of the gauge pointer resulting in a steady, flutter-free pointer.

Figure 1. How Dampened Movement Technology Works.

Ashcroft® PLUS!™ Performance Pros and Cons

This option has some advantages over standard dry or liquid-filled gauges:

You can learn more about PLUS!™ Performance in our brochure.

Ready to learn more?

Now that you understand the differences between liquid-filled pressure gauges, direct drive pressure gauges and gauges with dampened movement technology Ashcroft’s PLUS!™ Performance, you are in a better position to select the solution that’s right for your application. If you want to learn more about pressure gauges, here are a few related articles to check out:

- Ashcroft Gauge with PLUS!™ Performance - video

- Solid Front vs. Open Front Pressure Gauges

- How To Identify Your Pressure Gauge and Get the Proper Replacement

- How Do I Select the Right Pressure Gauge Range?

- How Often Should I Check the Calibration of My Pressure Gauge?

- How Does Temperature Affect Pressure Gauge Performance?

- How Much Do Mechanical Pressure Gauges Cost?

Feel free to contact us today to talk to one of our industry experts and get your questions answered. In the meantime, download our guide to learn the 5 Mistakes to Avoid When Choosing the Best Gauge for your Process.

Darren Lewandowski, Territory Sales Manager

Darren Lewandowski is the Territory Sales Manager (Channel/Distribution) at Ashcroft, responsible for the Northeast U.S., from Maine to Maryland. He started his career at Ashcroft in 2018 with 16 years of experience with flow control and measurement. He currently works with distributors and their end users in many areas, these include water/wastewater, food and beverage, high purity, and pharmaceutical to name a few, with a focus on providing solutions. In his leisure time, Darren enjoys traveling with his wife of 27 years, and proudly watching his daughters grow up to be wonderful and accomplished young women.